RWG (Repair & Overhauls) Limited

Overhauling the market

Embodying more than a quarter of a century of industry experience, turbine overhaul and repair business, RWG (Repair & Overhauls) Limited was established in 1990 as a joint venture between Wood Group and Rolls- Royce and has since grown to employ more than 500 employees internationally. The business traded under the name of Rolls Wood Group (Repairs & Overhauls Limited) until December 2014, when the company was rebranded to its current name of RWG, following Siemens acquisition of the Rolls-Royce Energy business. Throughout its history the company has  developed a strong global reputation with clients by combining its strong industry expertise with the management of several centres of excellence, located in the UK, US and Asia.

developed a strong global reputation with clients by combining its strong industry expertise with the management of several centres of excellence, located in the UK, US and Asia.

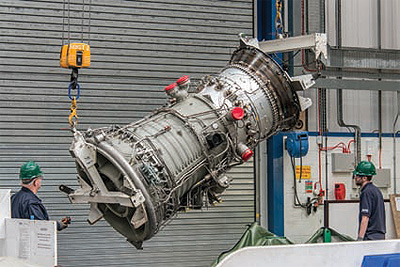

The company’s commitment to providing the highest levels of service has allowed RWG to emerge as an OEM-approved business that provides maintenance, repair and overhaul services for equipment. This includes Siemens industrial aero-derivative gas generators, which are used within power generation and oil and gas applications, as well as Rolls-Royce marine gas turbines that are employed in the operation of marine propulsion systems. RWG’s Industrial & Marine Business Director, Mark Forsyth explains: “We are predominantly a gas turbine repair and overhaul business and we focus on a specific range of gas turbines that is currently owned by Siemens and was formerly designed and manufactured by Rolls-Royce. We repair industrial equipment, which is comprised of Industrial RB211, Industrial Avon, Industrial 501K and Olympus gas generators and marine Spey, Tyne, Olympus and WR21 gas turbines. The main services provided by the business are workshop repair and overhaul operations relating to gas turbine engines, where we strip units down to clean and inspect the generators. We then rebuild the equipment using fully overhauled or new parts and then test each unit, which means that the turbines go through an extremely rigorous process before they are shipped back out to the client.”

In support of its repair and overhaul operations, RWG also maintains a comprehensive component repair capability, which is further supported by a wealth of industry experience that enables the company to offer a fully in-house service package. “One of our key differentiators is that we have developed our own dedicated workshop capability. This means that we have an extensive component repair division within the business that allows us to keep around 90 per cent of our component repair works fully within RWG. This is important because it allows us to closely manage considerations such as costing, quality and turn-around, enabling us to reduce the amount of replacement parts that go into the engines,” Mark elaborates. “Across everything that we do we see ourselves as a high-performing company in terms of the quality of the work that we undertake, the expediency of our services and the knowledge and depth of experience that resides within our organisation. We also offer other complementary operations such as field service support and we have our own in-house engineering team and laboratory, which makes us very self sufficient in the  field of equipment overhaul.”

field of equipment overhaul.”

During July 2016 it was announced that RWG had been awarded a three-year support agreement, with an option for a one-year extension, by the Abu Dhabi Marine Operating Company (ADMA OPCO). This will enable RWG to maintain the company’s operational fleet of Siemens Industrial RB211 gas generators. “We were delighted to secure this latest contract from ADMA OPCO which provides continuity of service and underpins the strong relationship between our companies.” Mark added: “A key element of the contract which is currently in the execution phase, is the provision of support engines to allow the client’s operation to continue whilst their own engines are undergoing overhaul.”

Commenting on another recent award, Mark said: “National Grid has awarded RWG a framework agreement to maintain their fleet of Siemens aero-derivative gas generators. This five year agreement provides continuity of support for scheduled maintenance and field services for National Grid’s Industrial Avon and Industrial RB211 gas generators. RWG and National Grid have a well-established and successful maintenance partnership spanning many years. National Grid’s decision to renew our framework agreement recognises the value derived from our long term relationship. National Grid has a large fleet of Siemens aero-derivative industrial gas generators including 30 Industrial Avon and 13 Industrial RB211 engines. This equipment, located at transmission stations across the length and breadth of the UK, provides essential mechanical drive capacity to ensure the energy needs of industrial, commercial and domestic users is met. RWG has provided on-site field support and workshop based major maintenance activity to National Grid for over 20 years.”

RWG’s focus is working in close collaboration with its customers to provide effective costsaving solutions, while seeking to deliver its services to new markets. “We are committed to developing solutions that help our clients to maintain their equipment efficiently and that is particularly pertinent in challenging times. We operate within a market in which there is not a large amount of new turbine equipment coming into service, so we need to work with current operators to help them maintain their existing fleets,” Mark concludes. “One area that we are looking to develop is the extension of our component repair capability, which could also lead us into new markets beyond industrial gas generator component repair.”

RWG (Repair & Overhauls) Limited

Services: Leading gas turbine overhaul and repair business