Sintef

Breaking new ground

Research and development is an integral aspect of every industry, as operators look to discover new processes and technologies to better overcome the challenges of the future.

This level of demand has given rise to external bodies such as Sintef – a non-profit polytechnic research foundation, which performs contract research and development for industry and the public sector. Such is the extent of this market that in 2007 alone Sintef carried out 6065 projects for 1900 unique customers.

Employing 2100 individuals, today Sintef is amongst the largest independent research organisations in Europe. Within this structure lies six research divisions, including Sintef Materials and Chemistry (Sintef M&C), which offers high competence in material technology, applied chemistry and applied biology. As such, the division’s main research areas are materials, energy, life science, and oil and gas, offering contract research, R&D partnerships, advanced engineering, industrial laboratory services, and select commercialisation.

In the case of the oil and gas industry, this research covers a wide scope of subject matter from fracture assessment of pipelines and corrosion protection, to the development and optimisation of materials with tailored chemical and physical properties. Work is also carried out in the field of hydrocarbon process chemistry with special focus on the development of materials for application within catalysis, adsorption and separation techniques.

As well as more traditional process technologies such as natural gas conversion, and oil refining, Sintef is currently very active within the emerging market of carbon capture and storage (CCS). Research director, Tore Aunaas elaborates: “The worldwide focus and possible contribution of CO2 to climate change has focused R&D to this scientific area for several years now. We have recently established a modern and full scale pilot plant for carbon capture research, and are co-operating with some of the most competent research organisations in the world in this sector.

“Another area of interest is our flow assurance capabilities and results. We are developing the next generation models for this area – the LEDA – which will be a very important tool for simulating and planning multi-phase pipeline transport in the future. Sintef is also active in establishing new companies, and one very interesting start-up is RESMAN. RESMAN tracer technology is a means of obtaining reservoir and well surveillance information without risky and costly intervention operations or cables, which require extensive modifications to completion hardware,” he continues.

“Another area of interest is our flow assurance capabilities and results. We are developing the next generation models for this area – the LEDA – which will be a very important tool for simulating and planning multi-phase pipeline transport in the future. Sintef is also active in establishing new companies, and one very interesting start-up is RESMAN. RESMAN tracer technology is a means of obtaining reservoir and well surveillance information without risky and costly intervention operations or cables, which require extensive modifications to completion hardware,” he continues.

However, as Tore is well aware, there always remains new ground to be broken: “Most important are those technologies and the knowledge that we still do not have – that will form the future and determine how this progresses. Our business aim is to be a major contributor to the creation, development and testing of new technologies. I believe that most of the future technologies will be developed within scientific areas that we have yet to combine in cross-over disciplines.”

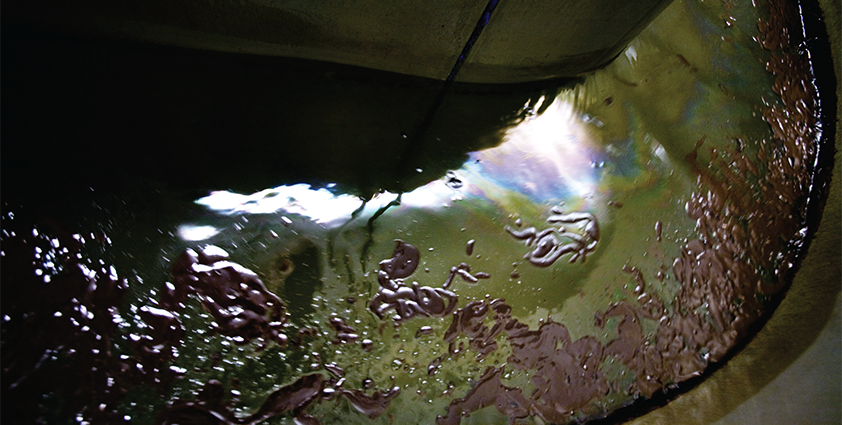

One department within Sintef M&C that is seeing particular results within the oil and gas industry is Sintef Marine Environmental Technology (MET), which performs experimental, monitoring and modelling studies in connection with acute and regular releases of oil and chemicals into marine and arctic environments. Both in the planning phase, and in the case of an accidental incident, knowledge of the expected drift and fate of an oil spill is crucial. As such, Sintef MET has developed modelling tools, which simulate oil drifts and fate, both from surface release and underwater leaks. This tool has been licensed worldwide and was extensively used during the Macondo incident to predict the spread of the spill.

In particular, Sintef MET’s work on arctic oil spill responses is looking to become ever more relevant as the industry begins to approach more technologically challenging areas – such as deep waters, harsh environments, remote areas, and environmentally sensitive sites – in the quest to secure new reserves. “These challenges will probably be both similar and different from those that we see today,” comments Tore. “There may be the need for remote technologies, new material technologies, integrated production and environmental monitoring to name a few. Sintef’s vision is ‘technology for a better society’, meaning that we do not only look into the enabling technologies across the value chain of the industry, but also deal with environmental issues, contingency and risk mitigating response technologies, and modelling.”

As exploration and drilling activities grow ever more widely spread within the arctic regions, it is vital that the oil industry has an understanding of the potential behaviours of such resources in the event of an incident. As such, in 2006 Sintef and co-operating partners in the US and Canada performed a joint industry programme on oil spill technology for arctic and ice-covered waters, which was sponsored by six oil companies and the Norwegian Research Council. Finalised in 2010, an output from this programme has been two new skimmer prototypes for mechanical recovery of oil in ice, and one prototype for vessel application of dispersants.

“The development of oil spill prevention and clean up methods has always been closely connected to planned petroleum activities in different parts of the world, or as a result of incidents. The shift of petroleum activities to more northern and arctic locations requires innovative new thinking related to implementing such procedures in low temperatures, seasonal darkness, ice, and generally poorer infrastructure,” describes Tore.

He continues: “We see that the use of chemicals in the oil spill contingency has gained more and more interest, primarily as dispersants and shoreline cleaning agents. Smart chemicals are a key word, and include an encapsulation of chemicals that can disperse under given conditions thereby increasing effectiveness. Optimisation of materials, such as in skimmers, to provide better adhesion to different oil types is also another area of growing interest.”

The international nature of the petroleum industry, and the reduction in easily produced resources, means that other new provinces are also being introduced for exploration and production to maintain energy demands. One such area is Brazil, where Sintef has recently opened a new office presence: “Sintef has contributed significantly to the development of the oil industry in Norway since the end of the 1970s, and we see that the competence and skills gained over these decades suits the growing demands of the industry in Brazil,” comments Tore.

“This region will be one of the leading oil and gas markets for the coming decades and we wish to take part in this technology and knowledge development. Our ambition is to establish a Brazilian research group of over 200 personnel in the next four to eight years, which is accompanied by the need to establish permanent infrastructure in the region. We are also closely following the development in other parts of the world, looking to Africa and the Gulf of Mexico, and Asia and Russia, where we are participating in a number of projects and initiatives,” he concludes.

Sintef – Materials and Chemistry

Services: Research