Sonar Equipment Services

Echoes out of the blue

In 1994 industry expert Les Ford founded Sonar Equipment Services (SES) and began working extensively with key components to produce marine survey equipment designed to meet customer’s needs.

With 15 years of experience, the company today supplies engineered and trusted products to the oil and gas industry, construction industry and renewable energy sector. The company was founded with the concept of offering customers a competitive edge by delivering integrated, forward thinking technology and innovative engineering solutions.

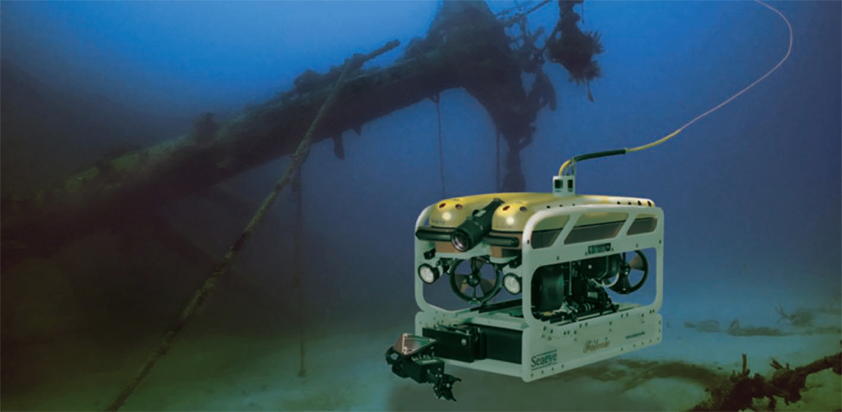

As a leading supplier of marine survey equipment SES has assisted clients, and worked directly, on a diverse range of subsea projects including cable surveys, UXO clearance programmes, wreck searches, pipeline inspections and much more. The business has successfully integrated and adapted marine technology solutions into various deep water applications on platforms ranging from ROVs to deep towed systems.

With the backing of knowledge gained within the industry, SES has developed a comprehensive range of equipment that is offered for both sale and rental to support customers in their offshore and near–shore operations. Located on the edge of the North Sea in Great Yarmouth, UK, SES has a modern workshop facility that is manned by a multi-disciplined engineering team specialising in maintenance, repair and modification of the extensive range of equipment.

To remain at the forefront of the industry the company has established a dedicated research and development team that has exceptional experience in delivering technical solutions when the client requires more than just a standard stock item. By taking a back to basics approach the company is able to develop adaptations that can meet the ever-changing operational requirements of its clients.

All the equipment offered by SES is subjected to rigorous test procedures in the in-house facilities before being released into the field and depending on the product SES has a range of test processes. In Great Yarmouth it has a purpose built, acoustically baffled water tank for the purpose of subsea sensor testing that utilises calibrated hydrophones and receivers with Fast Fourier Transform (FFT) analysis to produce fast and accurate measurements of system performance. For subsea equipment that is under extreme pressure when operating in deep water, SES has developed a pressure test chamber to simulate conditions where it can test components including transducers, subsea electronic housing and connectors.

In mid 2013 SES delivered its first multisensor ROV survey package to Calesurvey, a marine division of Calecore. SES integrated, tested and mobilised an array of subsea equipment for the client to use in marine surveys in Norwegian waters. The project is using environmental and geotechnical studies to survey pipeline routes. SES has supplied the technology that is fitted to the work class ROV at the centre of the survey, equipped with an extensive range of geophysical and bathymetry sensors. The equipment supplied included an Innova Matrix MKII fibre optic multiplexer that transports all survey data by a single fibre. This product was tested at its factory and the engineering team led a full sensor integration that ensured an efficient delivery onto the vessel. The SES Matrix design is a fully adaptable, compact plug and play interface solution that can integrate with all subsea sensors and equipment, and is suitable for any host platform.

Forming part of the company’s portfolio is a range of products and services for reliable termination of subsea electrical connections. With a cable moulding and termination facility Sonar Equipment Services has developed a technique for chemically moulded bonds using hot curing rubber that provides strong, watertight and oil resistant connections, which have been proven to last, even in very deep waters. The range is complemented by stainless steel and plastic cable grips designed to terminate cables towing lightweight vehicles. For higher load applications a high-grade stainless steel tow termination is available for armoured cables between six to 15 millimetres in diameter. The product is DNV tested to 90 per cent of the cable’s maximum breaking strain, and because the terminations are not reliant on a potting compound for strength they are well suited for field installation and maintenance.

SES regularly introduces new equipment, enhancing what it can offer clients. Recognising that the correct and safe operation of the products is vital to the success of projects and ultimately for the reputation of the company, the business has developed a series of training courses. The aim is to help customers maintain a competent and trained workforce through the programmes that accommodate all abilities and professionals.

The proven technology demonstrates the ability of SES to innovate solutions to clients’ requirements, and a track record of projects delivered on time and to satisfaction highlights the reasons demand has been high during 2013. As exploration and surveying continues it is the ability to identify and source the right technologies and then integrate these together to produce a reliable, functional and effective package that sets SES in good stead to remain a leading supplier.

Sonar Equipment Services

Services: Rental, sales and manufacture of marine survey equipment