SPP Pumps: From 1875 Patent Deal to Global Pump Powerhouse

Pump action

SPP Pumps was created in 1875 when a British engineer bought the patent rights of the pulsometer pump from an American, Thomas Hall. From this deal came the birth of the company as it is known today.

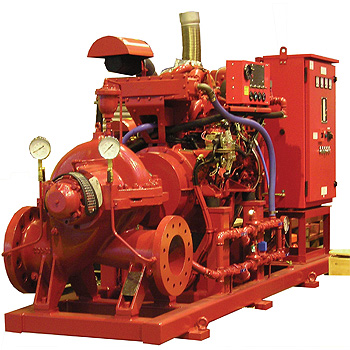

Its century long experience has made it one of the predominant pump manufacturing companies in the oil and gas industry. With its headquarters in Reading, the company mainly supplies five  areas in the water, fire, oil and gas, autoprime, service and spares sectors.

areas in the water, fire, oil and gas, autoprime, service and spares sectors.

Bob Tichband, business manager – Oil & Gas of SPP Pumps, explains: “We are a manufacturer of centrifugal pump packages, supplying the oil and gas industry, the water utility market, the industrial fire market and we also have a range of autoprime pumps for the building rental market, as well as a strong after-sales and service organisation. With the investment that is in the oil and gas industry at the moment, there is a lot of work around. We have been established in this market for 30 years as part of our core business and we feel that we have a lot to offer in this sector. We have a lot of strengths as a company; we are very focused in the markets we are in, we have excellent products, a proven track record and an excellent team of people who are very experienced and knowledgeable. We pride ourselves on the service we are able to provide and the products we produce.”

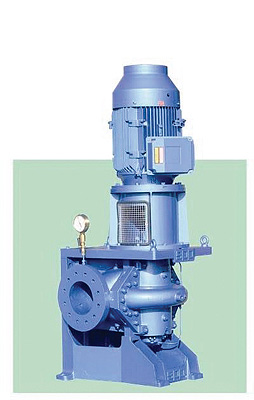

The company has recently been involved in the Pump Industry Awards, where it won Manufacturer of the Year award. This is a great achievement and follows on from the twe awards won last year for ‘Technical Innovation of the Year’ in response to the company’s new lowest life-cycle cost series suspended bowl pumps and the award for ‘Young Pump Engineer’ to John Hollins for his involvement with the lowest life-cycle cost range of high efficiency water pumps. Bob, talks to European Oil and Gas about these achievements: “we have an abso0lutely fantastic apprenticeship scheme, bringing through a lot of potential that has led to the young engineer award. The apprenticeship scheme is set in the Forest of Dean in the South of England and it is recognised as one of the best apprenticeship programmes in the industry. The other award was for our split case range of pumps; our pump design was redeveloped to be extremely economical with a longer life-span. It is a world leader in terms of pump efficiency and therefore has knock-on effects on power, carbon emissions and cost. It is an excellent product and we are pleased with the recognition it has recieved from this award. We are thrilled to have won Manufacturer of the Year Award this year and we will certainly continue to participate in these awards in the future”.

The success of the lowest life-cycle cost series is being enjoyed in conjunction with the company gaining its ISO 14001 accreditation from the LPCB (Loss Prevention Certification Board) for meeting the quality standards for its environmental management system. This is another high achievement for the company and is a demonstration of its environmental focus throughout its manufacturing process and general business activities. “Environmental issues are a big thing for everybody, especially in the oil and gas industry. A lot of the major companies will not do business with suppliers that don’t have this accreditation and it is a major part of our product development,” Bob comments.

The company is made up of over 230 highly experienced engineers, but over the years the oil and gas industry as a whole has seen problems with obtaining these skilled workers. Bob explains how SPP Pumps has coped with this: “In the current situation we are not in a better or worse situation than anybody else. Engineering is not the most popular vocation, so engineers are worth their weight in gold, but on the

other hand there are not that many engineering companies for them to flit between. We recruit in a number of ways but our apprenticeship programme is key in this. We try to recruit people from within the industry if they’re available and if not we bring in new people and train them up accordingly; there is no hard and fast rule to finding the engineers we need.”

On the Argyll platform SPP Pumps delivered the very first North Sea oil to come ashore over 30 years ago. Since then the company’s experience in the North Sea has allowed it to supply equipment to the most extreme environments around the world. SPP has supplied pumping equipment to many of the major international oil companies for a range of applications from Azerbaijan to Zimbabwe. Over 500 pumps have been installed on more than 80 fields around the world, with an equally impressive portfolio of onshore installations.

Bob reflects on SPP’s future: “I think that at the moment our oil and gas operations and our after-sales service are the two main areas that we will focus on. The after-sales service is not just limited to our products; it is a business in its own right. It will refurbish and service anybody’s pumps and valves and we feel it is a good business aspect to have. But one of the main strengths of the company is that we have other strings to our bow; if one area is not doing so well, inevitably another one is – all of the business areas make a contribution to the company as a whole. We have quite aggressive growth targets that we will be pursuing and as a company I feel we are going from strength to strength. We will achieve our goals purely from the force of our team and the development of our products. We have good engineering and service support, we really know our market, our customers and the specifications we are dealing with, and that will ensure our future in this business.”

SPP Pumps

Products Pumps and associated equipment