Strainstall’s 2014 Surge: Marking a Year of Growth within James Fisher and Sons PLC

A measured approach

Founded in 1965 and operating as part of the James Fisher and Sons PLC Group, 2014 has been a busy year for Strainstall as the company enjoys a period of increased activity and development.

The company’s main focus within the oil and gas industry is the provision of mooring monitoring solutions for all types of floating vessels to ensure safe operation as well as bespoke load monitoring solutions for a wide variety of applications including cranes, wireline load monitoring and riser monitoring. Strainstall was last featured in European Oil & Gas Magazine during March 2014 and has remained highly active during the second half of the year.

“Since March 2014 Strainstall has been extremely busy working on a number of interesting projects and developing the business as we continue to grow,” says managing director Simon Everett. “We have taken on more people in sales, production, project management, engineering and customer services as we continue to see good opportunities to further grow and develop the business. The oil and gas market is buoyant for us and we have just secured a major mooring monitoring project for a new offshore Tension Leg Platform, which will be delivered next year. We are also finalising the Moho Nord TLP tendon tension monitoring system (TTMS) and integrated marine management system (IMMS) for Total.”

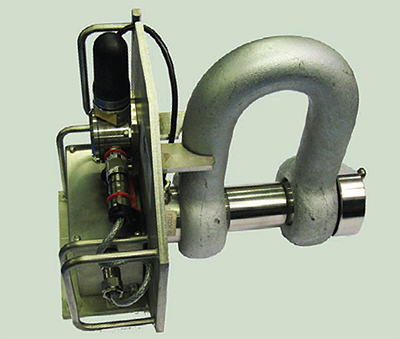

Further projects include the supply of load pins for the Shell Stones project located in the Gulf of Mexico, an ultra-deep oil and gas development that is currently the deepest production facility in the world at approximately 2900 metres. The project involves the use of a floating production storage and offloading (FPSO) that incorporates a forward mounted turret with a detachable buoy (buoyant turret mooring system or BTM), which allows it to weathervane in normal conditions and disconnect from the FPSO upon the approach of bad weather allowing the FPSO to sail for safer waters.

Strainstall was approached by the SBM Offshore Group to provide a solution by way of six specially designed load pins to measure the forces between the buoy and the FPSO as integral components of the detachable buoy system and a critical element in ensuring the safety of the FPSO and BTM. A bespoke design was required to comply with SBM’s unique requirements and  Strainstall was able to rely on its nearly 50 years of experience in designing special application load pins to provide the ideal solution. Furthermore SBM required a comprehensive documentation package in addition to the design, manufacturing and testing of the load pins. With a significant amount of experience in delivering specific packages for a wide variety of industries including offshore oil and gas, marine, industrial, aerospace and nuclear, Strainstall was again well placed to deliver a full turnkey solution.

Strainstall was able to rely on its nearly 50 years of experience in designing special application load pins to provide the ideal solution. Furthermore SBM required a comprehensive documentation package in addition to the design, manufacturing and testing of the load pins. With a significant amount of experience in delivering specific packages for a wide variety of industries including offshore oil and gas, marine, industrial, aerospace and nuclear, Strainstall was again well placed to deliver a full turnkey solution.

During May 2014 Strainstall also supplied its Vessel Motion Monitoring System (VMMS) for use as part of the Carbon Trust Offshore Wind Accelerator (OWA) programme. The VMMS was used during a sea trial to validate a wind turbine access system for the OWA programme, which aims to reduce the cost of offshore wind across three UK sites by ten per cent by 2015. “The VMMS supplied for the trial was a dual system taking measurements from two locations on the vessel,” Simon elaborates. “One of the sensors was located in the technician accommodation and the second was mounted on the vessel bow and transmitted data back to a laptop wirelessly. The key data being captured was heave, pitch and roll as well as the accelerations on all of these axes. The system was a great success and provided data that will be used to validate the access system and assist in defining weather windows for safe access of technicians from vessel to turbine.”

Indeed Strainstall has distinguished itself with technology and expertise that allows it to provide solutions in a host of hazardous areas, as Simon expands: “We have a great deal of hazardous area expertise within the company and have recently developed our wireless hazardous area technology to be used in zone one as well as zone two areas. We are using this technology to help customers remove cables from operational areas, improving safety and system reliability by eliminating the potential for cable damage.”

As the oil and gas and other sectors remain buoyant, Strainstall will continue to develop its focus on the areas where it has gained most expertise: “Our strategy is to focus on developing products for hazardous areas and subsea use, where we can utilise our experience to best give customers value,” Simon concludes. “We are focused on developing the next generation of mooring and structural monitoring solutions for offshore vessels and structures. With the complexity of offshore structures increasing all the time the need for monitoring solutions continues to grow. We are well placed to assist customers in these areas and in the last two years have provided systems for the largest ship and the largest floating dock ever made, reinforcing the confidence our customers have in us to deliver solutions in unique and demanding applications.”

Strainstall

Services: Load measurement and monitoring application solutions