Sub-Atlantic Ltd

All geared up

Sub-Atlantic Ltd has come a long way since its inception in 1997.

It has earned the valued position as the market leader in the design and manufacture of small to medium sized electric ROV systems including Comanche, Mohican, Super Mohawk, Mohawk, and Navajo electric ROV systems that are used worldwide by institutions ranging from oil and gas companies to oceanographic and military facilities. It is also the world’s premier manufacturer of ROV thrusters and components used in the manufacture of hydraulic work-class ROVs.

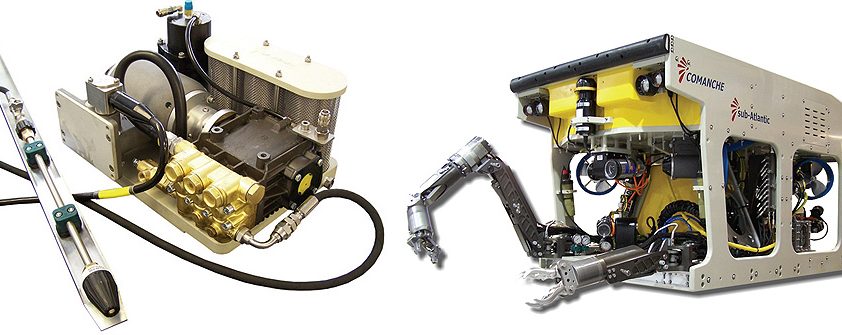

Apart from ROVs, Sub-Atlantic is also highly regarded for producing tether management systems (TMS), electrical and hydraulic thrusters, hydraulic power units (HPU), pan & tilts, valve packs, oil compensators, and specialised tooling packages capable of withstanding uninterrupted use in any offshore environment.

Among its newest ROVs available, the Comanche and Mohican have set new standards in electric ROV performance. Comanche, a small work-class ROV was specifically designed to carry two work  class manipulators. It is an efficient and economical solution for survey and rig support, incorporating a fully electric, seven thruster propulsion system configured to provide high thrust and lifting capability.

class manipulators. It is an efficient and economical solution for survey and rig support, incorporating a fully electric, seven thruster propulsion system configured to provide high thrust and lifting capability.

The Comanche has been designed using Sub- Atlantic’s small vehicle technologies making it extremely cost effective, and simple to operate and maintain by a two-man crew. It is equipped with additional power sources to allow the use of a 15 kW / 20 hp hydraulic power unit for running tools and work skids for rig support intervention tasks.

Like Comanche, the smaller Mohican ROV features a small diameter, low drag tether and high output brushless DC thrusters. Mohican is regarded as the mighty atom of the electric ROV market thanks to Sub-Atlantic’s Dynamic Vectoring TM system which enables it to direct thrust where it is needed. Dynamic Vectoring TM permits operators to direct thrust front to back to get to sites faster, then vector the thrusters to a lateral position on site to resist lateral water current and maintain steady position. Inspection with the Mohican is amply provided with four simultaneous video channels as standard, transmitted through a fibre-optic telemetry system for sharp, high quality video inspections. Sub-Atlantic has always been quick to enable customers to adopt new technology, integrating high definition television (HDTV) cameras systems to several of its ROVs. Mohican is also equipped with additional power sources for attachment of manipulator and tools such as its high pressure jetting and cleaning skid. The tooling options, compact size and ability continue operation in very high water currents thanks to its directional thrust meaning that, with over 20 units produced, the Mohican is a popular choice for platform inspection work.

Sub-Atlantic leads the market with its 3000 Volt, 400 Hz power transmission system from surface to ROV, permitting the use of small tethers, main lift cables and launch/recovery systems. The small diameter low drag tether system makes the Comanche vehicle particularly suited for long tether excursions on deep live-boating operations to 2000m (6000ft). The smaller Mohican ROV is additionally suited to long tunnel inspections and deep live-boating operations.

For deeper operations, it is essential that a tether management system (TMS) be integrated with the ROV system. The TMS design developed by Sub-Atlantic is renowned for reliability and simplicity, the most important features for any extreme design technology. A simple telescopic frame allows the TMS to be adjusted and accommodate a variety of ROVs and tool packages. Utilising a single drive motor principle, the tether tension on the drum is maintained at all times, ensuring accurate spooling is achieved.

Sub-Atlantic provides many components to ROV manufacturers, including the electric thrusters it designed for its own ROVs. No matter how well a thruster shaft seal performs, electric thrusters will suffer from water ingress in some form, requiring maintenance procedures to limit contamination levels. With this in mind, and reliability at the heart of Sub-Atlantic’s design philosophy, the company designed its SPE range of brushless DC thrusters to operate when completely full of sea water. This is achieved by its unique ‘Stator Shield’ system, which provides a water-blocked barrier between the stator and the rotor, creating two isolated cavities. The underwater industry regularly needs to undertake tasks that benefit from purpose-built equipment like this, and, with a wealth of knowledge providing specialised tools for working in such harsh environments. Sub- Atlantic has become the name to trust in design and production of tools to carry out the most complicated of operations.

European Oil & Gas looks forward to featuring Sub-Atlantic again in our next issue as the company reveals exciting new developments and gears up for the future. Watch this space.

Sub-Atlantic Ltd

Products: Electric ROV systems