Sulzer

Full stream ahead

Sulzer is a global industry leader with reliable and sustainable solutions for performancecritical applications. From its beginnings in Winterthur, Switzerland back in 1834, Sulzer has developed to become a leading player in its key markets.

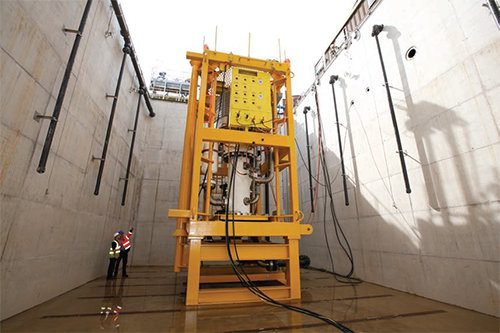

“We have acquired quite an extensive history in pump development throughout many decades, but in 2006 we started to look at subsea applications, driven by customer enquiries and requests for new competition in the market place but also our ambition to push research and development onto the next level,” highlights Matt Bourne, subsea business development manager. Having advanced its programme of works, complete with a team of specialists, the business embarked on a journey to enter the subsea pump market.

As part of its specialism is a range of services that includes mudline pumps for well stream boosting, water injection injection, as well as hybrid style pumps capable of handling gas entrained liquids. “The pump selection is derived from the actual process conditions to determine the best fit for not only steady state but also transient conditions; this ensures maximum maximum yield from the well whilst also maintaining uptime and reliability,” explains Matt as he goes on to discuss current trends.

“The subsea market has tracked the topside market, which has been driven by the decline in oil price, and in that climate, looking after costs becomes much more important. These costs extend beyond the actual CAPEX and include OPEX.” With the intervention cost to retrieve the equipment being high the requirement to keep focused on all areas particularly reliability  has increased in importance. “The demand for energy isn’t going away, albeit there is a slight lull in the price. We expect the market to come back up and when it does there will be an increasing demand to exploit the subsea oil fields,” he adds.

has increased in importance. “The demand for energy isn’t going away, albeit there is a slight lull in the price. We expect the market to come back up and when it does there will be an increasing demand to exploit the subsea oil fields,” he adds.

Currently present in all of the major oil basins, such as Angola, and areas off the West coast of Africa, Gulf of Mexico, and Brazil, working in the pre-salt province, the company also holds a firm grip on shallower waters such as the North Sea, where the introduction of subsea processing on Brownfield sites, can not only extend the life of the field but can put production back up to its best efficiency point. “Imagine a Brownfield site where if you are able to process the water out of the process stream before it gets to the topside facilities. This frees up a lot of the space, and allows you to use the topside space to make money instead of handling water which you want to get rid of,” highlights Matt.

It is this close alignment in thinking with what benefits the client that stands out as one of the company’s greatest strengths, combined in an approach to research and development that sees the company working with the ultimate end users and partnering with the right people. “It is in this sense that we have a very close partnership with FMC Technologies, working on the integration of the subsea pump into the field. Through this approach we have strengthened throughout our history in the oil and gas market, constantly pushing the boundaries. The global service network that we have has equipped us with a welcome knowledge that allows us to build just the right package for the customer,” explains Matt.

The time and effort spent reviewing the technology and work with the engineering teams and numerous clients has helped to ensure a final product that meets the most stringent criteria. “It is a two-way street in these frontier markets, and where new technology is being developed it is important to align with the ultimate end user throughout development. Isolated engineering does not work for either party in the long run,” he adds. The challenge of ensuring budgets are kept to, in an environment where high specifications are driving the product for long term reliability, is increasingly difficult, as Matt comments: “It is important to make sure that those factors don’t build up to a point where eventually the project is on hold due to cost escalation. It highlights the necessity for the vendor and the end user to work together to understand what is needed and how we can develop a product that meets the standards of reliability and other requirements without the addition of cost.”

Bringing together all parties to harmonise the requirements within the frontier markets, with new technologies, and specifications is also key for the purpose of standardisation across the market. “Single standards help lower the cost for everyone. As soon as you start to modify individual components of those specifications, vendors are no longer able to standardise their offerings and therefore the costs go up. The long term vision is realising the potential that is out there but harmonising the way that the players work together,” says Matt, concluding: “Geographically our focus for the next 12 months is on Brazil as well as the West coast of Africa. However, as we look more into the future, the arctic environment is interesting with the moving sea ice all year round defining the importance of operating on a subsea level.”

Sulzer

Services: Pump and process solutions

Issue 122 July 2015