Sustainable resource extraction transforms oil fields

By David Olutusin

Oil and gas fields often retain bypassed pay, which are areas or layers of the reservoirs with hydrocarbons that were neither recovered nor produced during the earlier stages of field development. Recognizing and maximizing opportunities for bypassed pay is key to maintaining a profitable field and can increase reservoir pay zones significantly – by as much as 50 percent in some cases. Identifying these bypassed pay opportunities is often challenging, especially in brownfields with significant existing surface infrastructures and hundreds of old wells within the subsurface. A combination of improved processes and methodologies supported by advanced tools can unlock significant opportunities to extend field life by several decades. Lessons learned from these methodologies can be applied at the onset of new green fields to maximize the field’s productive life at a minimum per-barrel cost while maximizing the return on investment (ROI).

Identifying bypassed pay opportunities

There are several challenges and concerns to consider when identifying bypassed pay opportunities. An initial development plan is typically created upon discovering a new oil field. The oil’s location is already known, but what isn’t necessarily clear is the cost associated with developing that field, such as the economics of extraction or production cost.

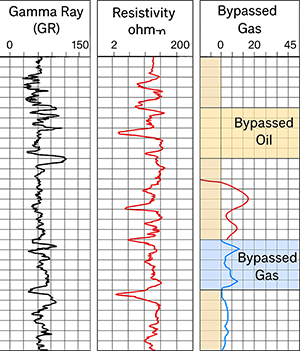

The concept of bypassed pay is fundamentally centered on the idea that oil will likely be left behind as the field is being depleted, although identifying where it is and how to get it often remains challenging. As the field matures and pressure decreases, it will no longer be sufficient to continually produce oil naturally in that field. Over time, as oil production declines, secondary and tertiary recovery efforts commence. The field is not dead. Rather, it has theoretically reached peak production. Peak production is often constrained by deployable technology or economic viability and profitability. Incorporating collaborative digital platforms and technologies supports the effort to identify bypassed pay opportunities and ensure the company achieves maximum ROI in the field (Figure 1).

Cloud computing

For an oil company with adequate network infrastructure, moving computing to the cloud reduces the risk of cyberattacks that can effectively shut down oil production. This induces significant losses or increases the maintenance and recovery costs across multi-site servers.

Cloud computing offers significant benefits, including enhanced real-time data analysis, increased efficiencies, and cost savings realized from multiple servers or data infrastructure. Technical personnel also benefit, as they can utilize remote access to data storage or acquisition to resolve operational issues faster than ever.

Machine learning and artificial intelligence

Machine learning (ML) and artificial intelligence (AI) change how oil companies recognize bypassed pay opportunities, which extends field life considerably. These tools are utilized to reassess a field built in the 1950s and provide data to construct a new reservoir model.

For example, advanced AI software enables building a new, robust three-dimensional image of a reservoir. Today, a new static model can be completed from beginning to end within a month, whereas ten years ago, it might have taken 18 months to build a single new model. With this improved model, it is possible to leverage existing data to identify previously bypassed pay opportunities.

Modern software platforms

Modern software platforms use programming and algorithms to read, learn, and model enormous datasets to create oil and gas reservoirs in alignment with an established body of knowledge, including depositional setting, reservoir characterization, and formation evaluation. Advanced AI software platforms can access ML code via plug-ins and use built-in algorithms to reprocess or reimage sand bodies, reservoir architecture, and fluid dynamics to produce a more accurate understanding of the reservoir. This enables the calculation of remaining oil volumes or bypassed pay opportunities.

Remote operations, monitoring, and control

Drone infrastructure can be advantageous in specific and limited situations, such as when oil and gas reservoirs are located beneath rugged or inaccessible terrains, including mountain ranges, valleys, swamps, or ravines. Previously, geoscience professionals were required to conduct fieldwork at locations of reservoir outcrops, wherever they existed. Now, modern drones with advanced camera capabilities record accurate measurements. This approach eliminates the need to deploy a crew to physically map the aerial or surface extent or land boundaries and reduces the time and cost required to map an oil field.

Recent innovations and emerging technologies

In addition to relying on technologies such as AI and ML, employing horizontal wells can improve oil extraction. This directional drilling technique digs at an angle of at least 80 degrees and enables access to oil that might not otherwise be attainable due to the reservoir’s unique shape or less-than-ideal accessibility.

Today, horizontal wells are more prevalent, as they help lower costs and improve oil extraction efficiency. They offer additional advantages over traditional vertical drilling. For instance, a horizontal well provides access to subsurface reservoirs that may not be accessible from directly above ground and allows one drilling pad to investigate a larger underground area.

Extended reach drilling (ERD) has similar benefits. Describing ERD as “essentially an advanced form of directional drilling or horizontal drilling technology,” researchers noted in a 2023 study that the technology “has the ability to achieve horizontal well departures and total vertical depth-to-horizontal distance ratios well beyond conventional directional drilling.” The authors also stated that, despite such advantages, ERD technology can increase the well process and create drilling issues resulting from the increased torque, drag, hole cleaning, and equivalent circulation density that it produces. “Overcoming these problems requires operational change to enable operators to address downhole challenges,” the authors wrote.

Remote operations continue to have a transformative effect on the industry. One 2024 study noted that remote technologies can revolutionize the oil industry by improving efficiency, cutting costs, and promoting safer and more sustainable practices. Researchers have focused on recent technological advancements and their impact on the industry to trace the evolution of remote drilling practices. Remote monitoring and control systems, for instance, are “fundamental to remote drilling operations,” using advanced sensors, telemetry, and communications technology “to provide real-time data on drilling parameters, equipment status, and environmental conditions,” according to the authors. In addition, operators can monitor and control drilling operations from centralized command centers, “ensuring precise and timely decision-making.” Ultimately, the challenges of bypassed pay opportunities will remain, but embracing these best practices and emerging technologies can help extend an oil field’s long-term productivity, profitability, and sustainability.

There are three key takeaways to consider when evaluating the importance of identifying bypassed pay zones and increasing a field’s production late in its life. First, new and mature oil fields can be developed without a negative environmental impact. Second, more oil can be extracted while prolonging field life, and third, productivity and sustainability can run in parallel.

David Olutusin

David Olutusin, MBA, PG, CPG, P. Geo, C. Geol, FGS, PMP, is a senior geologist with Kuwait Oil Company, and a subject matter expert in oil and gas field development. David is a board-certified professional geologist, certified petroleum geologist, professional geoscientist, chartered geologist, and project management professional, with over three decades of experience in oil and gas, project planning and execution. He can be reached at david.olutusin@gmail.com.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the official policy or position of the author’s employer.