The Forsyth Group

From concept to commissioning

The Forsyth Group of companies offers complete in-house solutions to a wide range of industries from distillation to oil and gas.

Since its foundation, the group has developed a range of services and products including the design, build, and where required, installation of:

- All types of distillation equipment

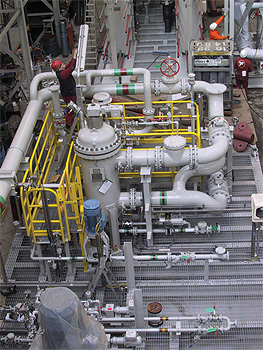

- Skid mounted modular units

- Large diameter cable, umbilical and flexi riser reels

- Pressure vessels, tanks and silos

- All types of large and small bore pipework

- Manufacturing in exotic materials

The use of unusual materials as mentioned above requires specialised equipment and facilities, and Forsyths addresses this need with its segregated clean shop, which has been designed purely for the storage and manufacture of exotic alloys. As its clients develop ever more innovative processes and equipment, Forsyths has found that exotic materials are increasingly specified for high-pressure applications, corrosive environments and rigorous conditions. As a result, its workforce’s skills have been honed to manufacture in specialist materials. It has over 165 approved weld procedures and is experienced in fabrication and welding of alloys, duplex and super duplex, cupro nickel, hastealloy and titanium.

The use of unusual materials as mentioned above requires specialised equipment and facilities, and Forsyths addresses this need with its segregated clean shop, which has been designed purely for the storage and manufacture of exotic alloys. As its clients develop ever more innovative processes and equipment, Forsyths has found that exotic materials are increasingly specified for high-pressure applications, corrosive environments and rigorous conditions. As a result, its workforce’s skills have been honed to manufacture in specialist materials. It has over 165 approved weld procedures and is experienced in fabrication and welding of alloys, duplex and super duplex, cupro nickel, hastealloy and titanium.

In addition to the clean shop, Forsyths’ other fabrication sites total over 6500 square metres of space and are fitted with modern efficient equipment. The company’s original headquarters in Rothes, Scotland remains its primary base, but it has been supplemented by three manufacturing facilities on the Moray Firth at Buckie, with two on the harbour side that offer direct load out shipping facilities. The Buckie quayside facility is ideal for manufacture, final assembly and load out of large topside and subsea fabrications up to 300 tonnes. It features 12 metres wide by 14 metres high access doors and 100 tonne internal cranage with a 14 metre under hook height. Buckie Harbour can accommodate a vessel of 86 metres by 16 metres beam and the port of Buckie has excellent shipyard, slipping, bunkering and chandlery facilities.

The Forsyth Group comprises three divisions – Forsyths, Grants (Dufftown) Ltd and Forblast Ltd. Forsyths designs and manufactures tanks, pressure vessels, pipework, modular skid units and process equipment for discerning blue chip clients in the distillation, onshore and offshore oil and gas, pharmaceutical, petrochemical and paper industries throughout the globe.

Established in 1911, Grants (Dufftown) Ltd has a well-respected reputation for fulfilling the electrical and instrumentation requirements for a large variety of industries – locally, nationally and internationally.

Forblast Ltd was formed in 1988, initially to service Forsyths requirements for high quality surface preparation and coatings. Since then, Forblast has invested in training, technology and plant and equipment and offers a global service to an international client base.

With many years of experience serving the oil and gas industry, Forsyths offers the same standards of 24-hour service and complete in-house solutions that it has provided to the onshore  industries for over a century. Its comprehensive service encompasses design using the latest finite stress analysis software packages, through to heavy fabrication, load outs, mobilisations and sea fastenings.

industries for over a century. Its comprehensive service encompasses design using the latest finite stress analysis software packages, through to heavy fabrication, load outs, mobilisations and sea fastenings.

An example of where Forsyths works within oil and gas is the area of large diameter reels for the storage and installation of subsea cables, umbilicals and flexi-riser systems. Its client list comprises of blue-chip companies and industry leaders, who appreciate the benefits offered by Forsyths’ experienced design team. The team uses the latest soildworks, AutoCAD and structural analysis and design computer software to custom design specifications to individual needs. This allows Forsyths to assume total responsibility for detailed design and fabrication to meet exacting offshore standards.

Forsyths’ competitive advantage in the manufacture of large diameter pipereels stems from the close communication links between its design and manufacturing teams. This results in tangible benefits to clients including reductions of up to 20 per cent in reel weight, allied to increased payloads, working loading, longevity and whole life costs.

Specialist computer software is also utilised in the design and manufacture of pressure vessels both to ASMEVIII and PD5500. In the area of pressure vessels, tanks and silos, Forsyths has the ability to manufacture specialised equipment for various industries including heat exchangers, columns, reactors, and deaerators. It also designs and produces complex energy and process pipework for UK and foreign clients within the petrochemical and industrial sectors.

Working with such demanding clients means that Forsyths has to prioritise quality, and as a result, the company is First Point Assessment and Achilles registered and audited, has experienced project management teams and has a fully accredited ISO9001 quality assurance system. It manufactures in accordance with the appropriate inspection authority, with full certification and traceability of materials and workmanship.

However, its strict attention to quality is not at the expense of delivery time. Forsyths’ contracts are successfully executed under stringent time schedules ensuring regular repeat business from leading distillers, pharmaceutical, petrochemical, and oil and gas manufacturers throughout Europe. Its IT links also allow real time access to its technical and sales staff, permitting accurate and frequent reports on projects.

Furthermore, with protecting personnel being such an important consideration in the offshore sector, Forsyths unfailingly adheres to stringent health and safety regulations during manufacturing. From concept to commissioning, the Forsyth Group offers a full range of disciplines and trades that mean clients are delivered a turnkey project efficiently and on time.

The Forsyth Group

Products Solutions for a variety of industries