The Tesco Corporation is a global leader in the design, manufacture and service of technology-based solutions for the upstream energy industry

Top driving the market

The company is focused on bringing cost-saving technology to the oil and gas drilling industry. Known worldwide as the company that provides customers with ‘Better Ways to The Bottom’, Tesco is the leader in research, development and supply of innovative products and services to reduce drilling costs and casing running, and improve safety and efficiency.

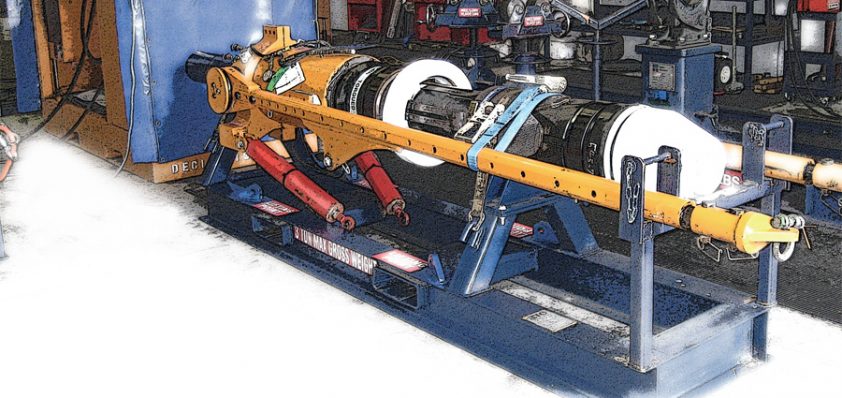

Tesco has an industry envied reputation and experience level with its ECI Top Drive systems, with over 50 worldwide units already successfully and safely in-situ.

At the end of Q2 Tesco will have in its fleet in Aberdeen two fully CE-ATEX rental ECI 900 HP 500 ton Top Drive units. These units will provide drilling contractors and operators with complete temporary or permanent cover for their Top Drive maintenance schedule and repair issues.

Top Drive sales manager Lyle Hopkins would also like to highlight a significant step forward in operational support with the company’s specifically designed Top Drive Service, Maintenance and Service Centre of Excellence located at its EURU base in Aberdeen.

Lyle says: “We have been servicing the European and Russian markets for quite some time now, but with the addition of these fully CE-ATEX rental units and our new maintenance centre here in Aberdeen, we can offer our current and future customers a level of quality and flexibility that exceed current offerings”

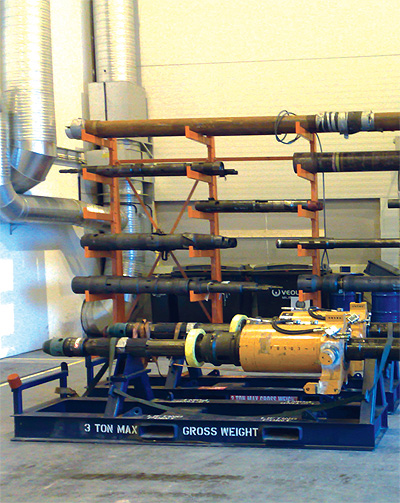

Opening in Q3 of this year, its primary function will be to service and repair Tescocorp Units for its ongoing operations in the North Sea, Norway, Central Europe, Russia and Africa.

Opening in Q3 of this year, its primary function will be to service and repair Tescocorp Units for its ongoing operations in the North Sea, Norway, Central Europe, Russia and Africa.

The facility will be 18,000 square foot with a 20 ton overhead crane and three main service bays giving an overall capacity to service four Top Drives at one time. Employing ten local service engineers, the company’s Top Drive Service, Maintenance and Service Centre of Excellence will hold sufficient spares and parts to satisfy all of its ongoing and future operations.

Key ECI 900 HP benefits

Some of the primary benefits of the ECI 900 TD are:

- The Tesco ECI Permanent Magnet Motor has the ability to hold stall torque for an indefinite period of time – very advantageous in certain drilling situations. An advantage of not having an AC motor is not developing excessive over heating and reducing the tendancy to burn out under similar conditions.

- The PA44 motor that Tesco uses is a totally sealed unit using water cooling. This prevents any ingress of contaminants during the cooling process, which prolongs the life of the motor. This means greater reliability. Because the ECI 900 are not dependant on forced ambient air passing over (non-sealed motors), the possibility of contaminants/moisture/foreign material being ingested into the cooling air duct, and the resulting interference with the non-sealed motors are subsequently reduced.

- As the Tesco 500 ECI motor does not have any brushes or commutation rings, the amount of wear is greatly reduced. As well as this the negative effects of rough drilling conditions are greatly reduced. Such as ERD wells and harsh bouncy top hole conditions, thus increasing longevity and reliability. Again due to not having an AC motor, the wear issue is negated.

- The Tesco Permanent Magnet Motors are sealed units which are water cooled through a modine cooler for the water cooling. A risk would be not sealed and depend on cooling via the use of ambient temperature, forced air. Water is a much more effective coolant than air at the ambient temperature

- Since the Tesco cooling pumps have redundancy the loss of one pump will not necessitate shutdown. No problems have been experienced with the cooing system to date. In fact due to the built-in redundancy in water pumps, the chance of downtime resulting is lessened. Water cooling also provides a more efficient medium for heat exchange. Tesco has tested its cooling system to 62C with no adverse effects/problems experienced. The Tesco systems do not have the risk issue of the loss of the ‘forced air fan’ that may require a shut down for repair

- The Tesco Top Drive, should the need arise, can be operated at reduced parameters with one or two permanent magnetic motors while the damaged motor is repaired or replaced. This results in less NPT giving cost savings. Other systems do not seem to be operated in this manner

- Tesco Top Drive (with swivel) weighs approx 5000 pounds less than a comparable top drive, and less rig horsepower/fuel effort is required to move on every cycle of the Top Drive in the mast resulting in reduced ton miles. This also means reduced slip and cut providing cost savings

- In the case of a problem, the Tesco Top Drive would require approximately three hours to be removed from the mast providing safer operations and less downtime

The idea of pushing other Top Drives to one side and picking up the Kelly oversimplifies the process. The presence of tugger lines, tong lines etc. in the mast area for Top Drive storage would create severe problems. The presence of a Top Drive hanging in the mast not connected to hoisting equipment would also present possible safety problems which complete removal would avoid thereby eliminate cluttering up the mast.

Should a problem develop with the rig power supply, the Tesco ECI Top Drive power supply cables can be disconnected from the Top Drive, a crossover (x.o) sub installed below the existing mud saver valve, and the Kelly screwed onto the x.o sub. At this point drilling (with the Kelly and Kelly bushing) can be resumed. The Top Drive is left in place and the Permanent Magnet Motor is allowed to free wheel with no damage resulting to the Top Drive, and Minimal downtime being experienced. Damage to the motors would be a major concern if this was not the case.

Tesco Corporation

Products: Drilling systems