Tranberg AS

Lighting the way

Leading provider of heating, lighting and enclosure systems for the oil and gas industry, Tranberg AS was established in 1901 in the Norwegian oil capital of Stavanger.

Over the years, Tranberg has developed its products and services, and today designs, manufactures and supplies high quality electromechanical products for use on ships and offshore installations. Its location right in the centre of North Sea oil and gas operations means that Tranberg is in close proximity to most of its main clients, and as a result the company can develop and test products in close co-operation with customers.

With a range of products including lighting, cable glands, junction boxes, electrical heating, enclosures and controllers, Tranberg’s equipment is capable of performing under all climatic conditions, from arctic cold to tropical heat.The company also has dedicated teams that implement a high level of quality and reliability in Tranberg’s products. They also ensure that high product quality and durability are maintained through the delivery of equipment to the demanding maritime and offshore markets, which is key to upholding the strong reputation Tranberg has held in these industries for the past 109 years.

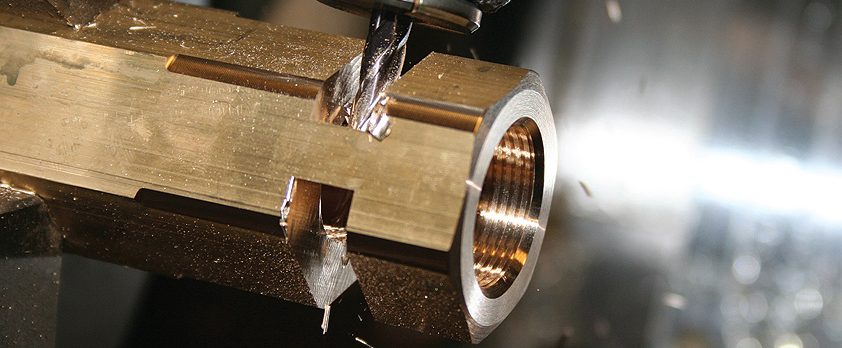

Reidar Abrahamsen, operations and sales engineer at Tranberg, believes that the key to the company’s success lies in its workforce and its innovative approach to the production process. With a quality assurance system certified  by Det Norske Veritas to ISO 9001:2008, Tranberg has the accreditation to support its reputation as a provider of high quality equipment. Reidar explains how the focus on quality has allowed the business to progress: “Our flexible production and dedicated workers have made it possible to adapt to quickly changingdevelopments. These include the increased demand for smaller equipment with lower total lifetime costs and products suitable for use in arctic environments.”

by Det Norske Veritas to ISO 9001:2008, Tranberg has the accreditation to support its reputation as a provider of high quality equipment. Reidar explains how the focus on quality has allowed the business to progress: “Our flexible production and dedicated workers have made it possible to adapt to quickly changingdevelopments. These include the increased demand for smaller equipment with lower total lifetime costs and products suitable for use in arctic environments.”

Ever since its formation, the company has committed itself to its customers and the provision of the best products and services to meet their requirements. Over the years the company has grown quickly, expanding into a new workshop and location in Stavanger, while also extending its product range to include navigation equipment, cable glands, heat tracing products, and offshore equipment.

In recent years the production of Topside Umbilical Termination Units (TUTU’s) has played an increasingly important role in Tranberg’s product portfolio. The company has been awarded several projects for offshore installations and is now looking at upcoming wind farms as a possible new market.

The latest major development for Tranberg came in 2006 when leading provider of explosion protection equipment and services, R. Stahl Schaltgeräte became the company’s new owner. Reidar comments: “R. Stahl is one of the global market leaders in explosion protection, and our integration into the group, has ensured that we are now a part of its international distribution network. Within the R. Stahl Technology Group, Tranberg serves as the competence centre for lighting, de-icing services for ships and process heating systems.”

Under this new ownership, Tranberg has been able to extend its market reach. The company currently supplies its products to the oil and gas business and related suppliers in Scandinavia and the North Sea area, as well as the international shipbuilding industry. Reidar describes how the company will look to develop and expand its business as part of the R. Stahl group: “We will continue to develop our sales operation, particularly with regards to the global shipbuilding industry. As a member of the R. Stahl Technology Group, activities in several new geographical areas have been established, and we will look to grow these considerably in the future.”

Having recently developed a complete range of advanced searchlights, Tranberg is now able to supply a complete outdoor lighting package for use onboard ships. The new searchlights demonstrate the business’ strong reputation for the high quality, precision and flexibility of its products. Incorporating the company’s expertise in electrical heating systems, the new range supports Tranberg’s increased focus on the needs of oil and gas supply vessels for operations in arctic areas.

Ever since the Ekofisk field was first discovered in 1969, Tranberg has been involved in its development. Most recently the company supplied the complete heat-tracing system for Snøhvit (Hammerfest Gas Plant) and significant parts of the heat tracing to Ormen Lange. After these two large projects, the activity in the Norwegian oil and gas market has been dominated by MMO-activities. Following the planning for the Greater Ekofisk Area Development Project, Tranberg has been named as one of the project’s suppliers, giving the business the opportunity to attain contracts for these newbuildings.

As the company moves forwards, it will continue its plans to grow geographically and to extend its services. However, the effects from the recession on the shipbuilding industry in particular have had a hindering impact on Tranberg over the last year. While oil and gas activities have also been temporarily affected, the current high oil price means there is plenty of opportunity for new investments, particularly on the Ekofisk field, which is an area that Tranberg is hoping will secure it plenty of work in the future.

Tranberg AS

Services: Heat tracing and marine systems