Established in 1896, Trelleborg Offshore Norway has been a key supplier of new products and tailored solutions to the oil and gas industry for decades

Innovation is key

In more recent years, the company has undergone a number of organisational changes that has seen it become part of global engineering group Trelleborg.

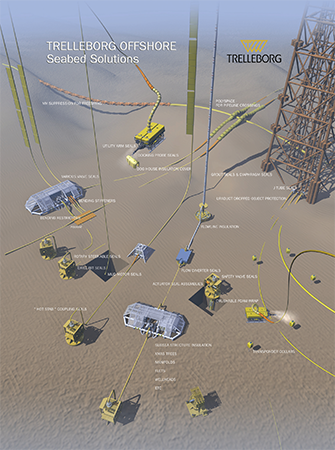

Trelleborg Offshore Norway is also notable as a world leading producer of rubber products for offshore applications. In terms of material properties, rubber is a particularly versatile material with unique physical capabilities that make it ideal for many applications. This includes protection of other materials against corrosion, fire, vibrations, and wear and tear. By exploiting elements of these properties and advanced polymer technology, Trelleborg Offshore Norway has been able to create a leading range of corrosion and fire protection materials, flexible connections, and thermal insulation systems.

However, Trelleborg Offshore Norway sees its role as beyond merely manufacturing standard products: “We do not sell products, we sell systems and technologies within the fields of thermal insulation, passive or active fire protection, and flexible piping,” notes Hans-Leo Hals, managing director of Trelleborg Offshore Norway. “Our strength for the last 20 years has been based upon a focus on developing new technology in line with customer demands. We’re also able to solve individual challenges and special applications by creating bespoke products.”

The results of such work include Trelleborg Offshore Norway’s pioneering and patented flexible piping system, Elastopipe. Suitable for various applications such as Firewater systems, drain systems, chemical and hydrocarbon tansport. Elastopipe benefits from a minimum lifetime of 30 years and the lowest life cycle cost of its competitors. Another key product is Vikotherm – a solid rubber-based coating for subsea thermal insulation. After 20 years in operation, Trelleborg Offshore Norway is now poised to introduce its new second generation Vikotherm II product.

The results of such work include Trelleborg Offshore Norway’s pioneering and patented flexible piping system, Elastopipe. Suitable for various applications such as Firewater systems, drain systems, chemical and hydrocarbon tansport. Elastopipe benefits from a minimum lifetime of 30 years and the lowest life cycle cost of its competitors. Another key product is Vikotherm – a solid rubber-based coating for subsea thermal insulation. After 20 years in operation, Trelleborg Offshore Norway is now poised to introduce its new second generation Vikotherm II product.

“Vikotherm II is a flexible material that is of real interest to our customers as unlike our competitors’ products, it can withstand the huge stresses associated with starting up well production. Other products in this market can crack under such circumstances, hotter conditions can cause these to hydrolyse and degrade. The rubber construction of Vikotherm II means that when a high stress is placed on the material, such as in well start-up and operation, it can absorb the mechanical load without damage. The product can be used to protect thermal or subsea structures at depths of over 3000 metres, and can withstand temperatures up to 155 °C it is also excellent for corrosion and HISC protection (Hydrogen Induced Stress Cracking),” explains Hans-Leo.

Another major advantage of the Vikotherm II system is that Trelleborg Offshore Norway is able to perform the coating process on site for customers worldwide, as part of its mobile factory concept. Whilst in the past this activity would have taken place within the company’s Norwegian facility, the ability for Trelleborg Offshore Norway to apply materials in situ opens up new markets, and opportunities for the business.

The continued success of Elastopipe and the passive fire protection side of the business, as well as the greater focus on subsea thermal insulation, has meant that Trelleborg Offshore Norway has seen its customer base increase over the last three years, but remaining fixed on the major oil companies and engineering houses. “At this time we also took a strategic decision to build a new plant in Brazil,” reveals Hans-Leo. “This was mainly due to the demand for local content, as opposed to transporting our products into the country, from major clients such as Petrobras. We are already seeing a huge benefit from this development ahead of the factory’s opening later this year.

“Today our biggest challenge lies in securing capacity, in both operations and engineering. We are in a booming market, and a lot of products have been released, so it’s important for the business to capitalise upon market share. To this end we are benefiting from our relationship with Trelleborg and its global presence, which has enabled us to create internal partnerships in key markets such as Brazil, but also South East Asia and Australia. This includes a new co-operation with Trelleborg in Singapore in order to grow our business in that region,” he adds.

With the subsea market increasingly moving into greater depths, the associated high temperatures and pressures present even greater challenges for suppliers of protective materials. Hans-Leo concludes with how this will impact upon Trelleborg Offshore Norway’s intention to increase market share within its three core sectors – thermal insulation, passive fire protection, and flexible piping: “Our strong focus in developing new technology in association with customer needs is a key aspect of this. We already have new technologies in the pipeline, that are not yet ready to launch, but are within the passive fire protection field. After the Deepwater Horizon incident in the Gulf of Mexico we’re seeing a lot of new rules and regulations coming up with regards to safety, which fits in very well with the material technologies that we can offer.”

Trelleborg Offshore Norway

Products: Flexible piping, fire and thermal protection