Tyco Flow Control

Building on success

With 17 manufacturing plants in Europe, the Middle East and Africa, Tyco Flow Control brings together some of the most renowned and respected brands in the industry, including Anderson Greenwood, Biffi, Crosby, Dewrance, Fasani, FCT, Hindle, Keystone, KTM, Morin, Narvik, Raimondi, Vanessa and Winn.

The last but one of these – the Vanessa brand – which was acquired by Tyco in 1997, has established an unrivalled reputation for design excellence and product quality in the field of valve manufacture. It is responsible for a unique, entirely new concept in valve technology – the metal seated, zero leakage, rotary process valve a product that has revolutionised the valve market. With the continued support of Tyco, Vanessa’s manufacturing facility, based just south of Milan at Lugagnano Val d’Arda has continued to grow and expand into one of the industry’s most efficient  and modern manufacturing facilities.

and modern manufacturing facilities.

Most recently, Tyco has invested a total of $15 million in a four-part plan at the site, which is due to be completed in February 2009, expanding it from 30,000 to 50,000 square metres. The first of the four phases of the plan, an additional test facility and assembly area for larger valves, was opened by Tyco in September 2007, whilst phase two, involving construction of additional warehouse, office space and machine shops, was completed early this year.

Beyond this initial work a new road is being constructed at the rear of the facility, with the 900 square metres of land that was the site of the former road being used to expand the current manufacturing area during phase three of the project. Finally, the last stage will involve the addition of a further 2000 square metres of space to the site in spring 2009.

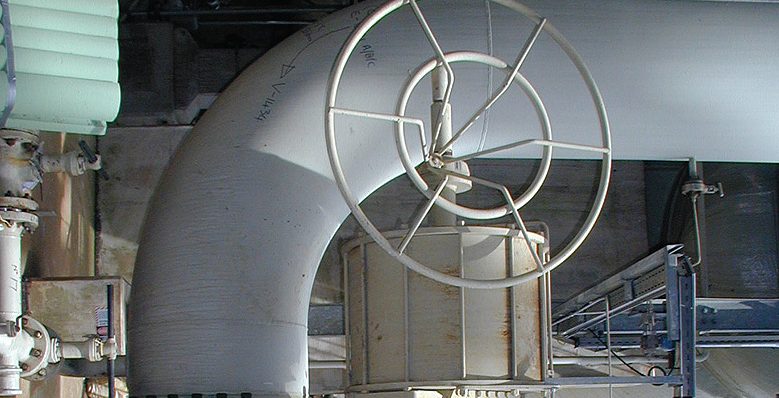

These improvements build on the impressive work that has been taking place to strengthen and expand the capabilities of the Vanessa facility in recent years. The business has maintained its competitive edge in the market not merely through the development of industry leading valve technology, but by continuously investing in state-of-the-art manufacturing equipment and health, safety and environmental systems.

In addition, Vanessa focuses heavily on applying flow management and lean manufacturing techniques to ensure the highest levels of quality and efficiency within the site. The first of these steps was taken during the mid-1990s when the business re-organised all its systems of manufacture and implemented Class A manufacturing resource planning. Subsequent improvements included the application of lean strategies to the company’s integrated manufacturing cell, which is a fully independent production site that is operated using advanced material techniques based on demand flow technology. The adoption of such programmes has benefited the business significantly, allowing it to optimise and improve the overall production process vastly.

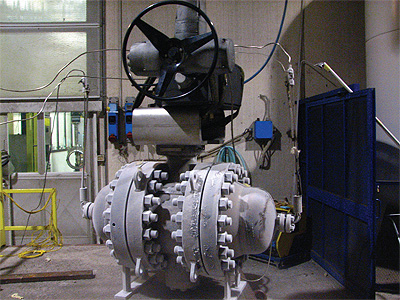

This basis provided a highly valuable model to adapt and apply to the rest of the factory. In 2004 a new programme of analysis was implemented as part of a Six Sigma initiative introduced  throughout the facility with the aim of reducing variation in products and processes, shortening cycle times and increasing capacity and revenue. Implementing such practices has seen the business lead the way in valve design, manufacturing a range of triple offset, quarter turn rotary process valves made for zero leakage shut-off where metal seating is required. Its innovative Series 30,000 valve is different to others in the market in that it adds a unique third inclined cone offset that allows camming, and eliminates all seat-to-seat rubbing throughout the valves complete rotation, thus completely eliminating the possibility of leakage between the seat and the seal.

throughout the facility with the aim of reducing variation in products and processes, shortening cycle times and increasing capacity and revenue. Implementing such practices has seen the business lead the way in valve design, manufacturing a range of triple offset, quarter turn rotary process valves made for zero leakage shut-off where metal seating is required. Its innovative Series 30,000 valve is different to others in the market in that it adds a unique third inclined cone offset that allows camming, and eliminates all seat-to-seat rubbing throughout the valves complete rotation, thus completely eliminating the possibility of leakage between the seat and the seal.

The unique design also optimises the contact angle between the seat and the seal – which in most valves is between three and six degrees – to eliminate the possibility of jamming and ensure lifelong seal capabilities. Using a resilient duplex stainless steel ring, the Series 30,000 is ideal for a large number of oil and gas, power and petrochemical applications, and suitable for the most demanding environments. Furthermore, with safety in mind, the solution is inherently fire safe and is certified to the most stringent of fire safety standards, including API607.

Working through recognised brand names such as Vanessa, Tyco is able to provide one of the most complete ranges of products, including ball valves, control valves, check valves, globe valves, knife gate valves, and rotary valves. The company’s reputation in the industry is built upon its dedication to quality and customer service. It works closely with its clients to provide a complete catalogue of valve management, training, servicing and testing facilities and carries out an extensive after-sales repair and testing service.

This level of service, combined with a continued focus on growth and expansion of the business, has seen Tyco strengthen its position as one of the world’s leading suppliers of valve technology. Such commitment to the industry, together with further plans for investment in technology and manufacturing capabilities, means that future looks bright for the business.

Tyco Flow Control is one of the world’s leading manufacturers of flow control and heat tracing products and solutions, employing around 15,000 people in nearly 40 locations worldwide. The business, which offers clients an integrated capability of single source proprietary flow control products and services, provides products to the oil and gas, power, chemical, process, and food and beverage industries.

The organisation represents a total global network that encompasses the manufacture, marketing, sales and after-sales support of the largest, most comprehensive, range of industrial flow control products in the world, including valves, actuators, controls and associated instrumentation. It operates as one of the major business segments of Tyco International Ltd, which is a diversified, global business that supplies valves and controls, security products and services, fire protection and detection products, and industrial solutions to customers in more than 60 countries across the world.

Tyco Flow Control

Products: Flow control products and heat-tracing solutions