Ulstein Verft

Turning visions into reality

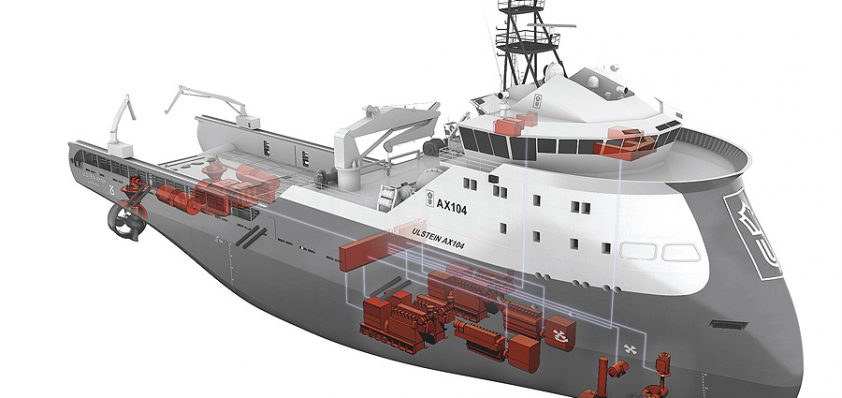

Ulstein Verft is one of the world’s foremost suppliers of advanced vessels, including anchor handling tug supply vessels, platform supply vessels and specialised and multifunctional vessels.

The shipyard serves as the Ulstein Group’s development base for the detail design and assembling of capital and equipment intensive specialised vessels, and is also the Group’s most important expertise base for carrying out building projects.

The main yard is in Ulsteinvik, Norway, but there is also a department in Vanylven, Norway, where steel-sections for the main yard are built. The steel intensive components of the hull are  manufactured at Maritim-Shipyard in Poland and production there is followed up by Ulstein Poland Ltd. In addition, Ulstein Verft is co-operating with and sub-contracting hulls to a shipyard in Ukraine, JSC Zaliv, located in Crimea, which has facilities for large vessel construction.

manufactured at Maritim-Shipyard in Poland and production there is followed up by Ulstein Poland Ltd. In addition, Ulstein Verft is co-operating with and sub-contracting hulls to a shipyard in Ukraine, JSC Zaliv, located in Crimea, which has facilities for large vessel construction.

Ulstein Verft is part of the larger Ulstein Group. This organisation’s success has been based on the continuous exchange of knowledge between ship owners, designers, equipment manufacturers, engineers and shipbuilders. This unique collaboration has allowed the Verft shipyard to build advanced vessels for the most demanding operations. The business’ range includes anchor handling vessels, the Ulstein Aseries; platform supply vessels, the Ulstein Pseries; and specialised multi-functional vessels, the Ulstein S-series.

Ulstein Verft began life as a small, familyowned shipyard operating in the repair industry. During the 1960s, the business expanded significantly and started to build the first few Ulstein ships. As a result of the success of these vessels, Ulstein made some strategic acquisitions – adding to its offering companies producing parts for advanced offshore ships.

In 1998, Vickers, a UK based business, bought the equipment and design sectors of the Group, which then became Rolls Royce. Consequently, Ulstein Verft was left with a five-year agreement to not sell ship designs and engineering packages outside of the Ulstein Group. During this period, the company spent a significant amount of time developing new ship designs and building vessels at the Verft shipyard. One of the most innovative developments to come out of this period was the Ulstein X-Bow.

In April 2005, the Ulstein Group introduced the X-Bow, an innovative bow solution with improved seakeeping abilities, noted for its revolutionary design and appearance. Its inverted bow is designed to improve handling in rough seas, increase speeds and lower fuel consumption.

In 2006 the first ship with the Ulstein X-bow, the anchor-handling vessel, Bourbon Orca, was put into operation. Shortly after, platform supply vessels, Bourbon Mistral and Bourbon Monsoon,  began services. Feedback from these ships has been very positive and as a result, from 2008 to 2010, 20 vessels with the innovative bow will be delivered to seven shipping companies around the world. Ulstein’s most recent X-Bow contract is with EDT Offshore. This project includes design and equipment package deliveries for two Ulstein PX105 platform supply vessels.

began services. Feedback from these ships has been very positive and as a result, from 2008 to 2010, 20 vessels with the innovative bow will be delivered to seven shipping companies around the world. Ulstein’s most recent X-Bow contract is with EDT Offshore. This project includes design and equipment package deliveries for two Ulstein PX105 platform supply vessels.

In addition to this, the largest Ulstein X-Bow vessel to date, the Island Constructor, was launched by the company in February 2008. This ship will be delivered to Island Offshore at the end of May. As the fourth ship to be developed using the innovative X-Bow, the Constructor, measuring 120 metres long and 25 metres wide, is the first in the Ulstein S-series with Ulstein Xbow to be designed. The ship has been fitted with a large tower in order to carry out state-of-the-art offshore well intervention services.

Gunvor Ulstein, CEO for the Ulstein Group comments: “We have spent a great deal of time in recent years developing new products, designs and work processes. We will continue our innovation efforts and create new and ecofriendly solutions. Furthermore, systematic and solid innovation work will nearly always bear fruit directly or indirectly in the long term.”

She continues: “Through this forwardthinking attitude, the Ulstein Group has gone from being a strong local player to a global contender. Our strategy is therefore sustainable growth on a global scale. If we want to continue to be competitive, it is essential that we use the possibilities provided by globalisation.”

The Ulstein Group is complemented by a number of expert divisions in ship design, shipbuilding, electrical solutions and control systems. Aside from the shipyard, these include Ulstein Es-cad, Ulstein Slovakia, Ulstein Elektro, Ulstein Belga Marine, Ulstein China and Ulstein Design.

Recognising the demand for local shipping, approximately a year ago, the Group acquired the Turkish design company, Es-Cad, which had solid design expertise within the short-sea shipping sector. Ulstein Es-Cad was therefore, established on 1st January 2007 in Istanbul – a prominent location for European shipbuilding. This division is now a centre of expertise for merchant and short-sea shipping.

Furthermore, another string has recently been added to the Group’s bow with the establishment of Ulstein International. This division’s main task is realising the organisation’s strategy for globalisation and growth. This includes both acquiring new companies and developing existing businesses. Ulstein International has recently headed the project groups for the acquisitions of the Dutch company Sea of Solutions and the Norwegian firm Marine and Mechanical Technology (MMT).

Tore Ulstein, CEO of the division comments: “The acquisition of these two businesses is important for the future development of the Group. With Sea of Solutions we have acquired a larger portfolio of products and services and greater expertise in project development. In addition, the Group will use MMT to establish Ulstein Engineering in spring 2008.”

At the start of its 90-year history, the Ulstein organisation was a strong local player, building advanced vessels through the high quality Verft shipyard. Through these strong beginnings, the business has now developed into a serious contender in the global shipping market.

Gunvor concludes: “If we were to define the core expertise of our corporation, it would be ‘integration’. Such expertise is in demand and we will keep developing and enhancing it in the years to come. To succeed in this endeavour, our employees and the companies in our Group must work closely together. When one of our divisions succeeds, we are all happy because we know that our strength lies in our corporate teamwork.”

The Ulstein Group

Products: Advanced vessels