WAGO Norge

Springing into action

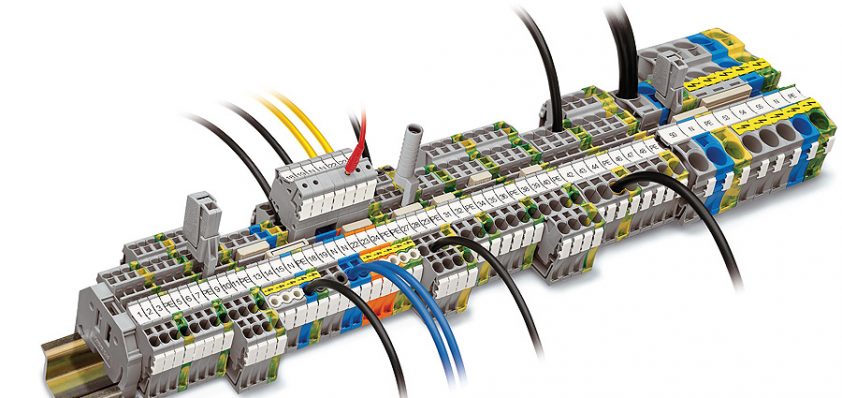

WAGO began with the simple idea of finding an alternative to the normal screw-type connection in the connection technology field, using its innovative know-how to develop spring clamp terminal blocks.

Its technology has long since represented the worldwide standard, to the extent that modern electrical connecting systems and automation without WAGO technology is unimaginable.

Leif Midboe is the general manager of WAGO Norge, which is a subsidiary of the privately owned WAGO in Germany, which is a close-knit, family run company. He elaborates on how WAGO came to produce safe and reliable devices and systems worldwide: “The organisation was established in 1951 in Germany and its products were distributed to Norway through different distributors, so in 2005 WAGO decided to start up a division in Norway to increase business in there. We’ve witnessed a healthy turnover increase each year since and we have four times more sales than before WAGO had an operation in Norway.

Leif Midboe is the general manager of WAGO Norge, which is a subsidiary of the privately owned WAGO in Germany, which is a close-knit, family run company. He elaborates on how WAGO came to produce safe and reliable devices and systems worldwide: “The organisation was established in 1951 in Germany and its products were distributed to Norway through different distributors, so in 2005 WAGO decided to start up a division in Norway to increase business in there. We’ve witnessed a healthy turnover increase each year since and we have four times more sales than before WAGO had an operation in Norway.

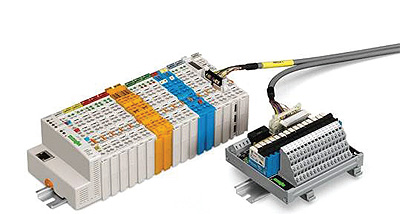

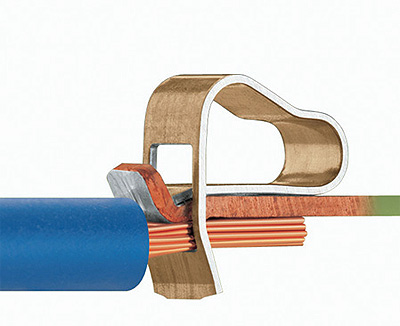

“The whole foundation of WAGO is based upon using springs instead of screws on electrical connections. We patented the cage clamp principle in 1974 and it has been the basis for the development of WAGO, both on an international level and in Norway. In the early 1990s we started off with remote automation systems and enjoyed great success in Norway because the WAGO system is ATEX approved and very small. It’s been well received by the oil and gas industry in Norway, as well as the shipping industry. This is important because with ships there are a fair few applications where ATEX approval is required.”

When WAGO invented spring clamp technology, it astutely ascertained that incorrect assembly and poor maintenance led to some examples of grave consequences for connections where screw-type terminals had been used, such as loose contacts, short circuits and electric shocks. WAGO cleverly countered these risks with quality-assured and cost reducing components, courtesy of its investment in the development of new products for electrical connection technology and automation.

“If we look at the terminal blocks with spring clamps, the technology has been embraced by clients who have critical operations,” Leif reports, commenting on the uptake of WAGO’s technology. “The spring is very important because if there’s vibration or unfortunate environmental issues, a spring will always make sure there is a 100 per cent connection. On an oil platform there are vibrations and temperature changes, and a spring ensures that a connection is maintained no matter what. With a screw, an oil and gas operation will typically have maintenance routines in terms of retightening the screws, but our spring terminals are connected once and operators never need think of them again. In respect of automation, the integration of non-Ex and Ex signal cards on one rail in a compact building format was something that the oil and gas industry was looking for.”

Indeed, WAGO Norge has enjoyed success with its spring terminal blocks with players in industry, as Leif explains: “Our customers are generally machine builders but oil and gas businesses have really embraced this technology. They are subscribing to the idea of springs over screws. People in the sector have always been described as conservative but I’ve found that views have turned around quickly, in terms of applying this technology to new projects. We’re very proud of this fact and feel that this change in the business has come about because we established ourselves in Norway in 2005.”

Considering the company’s emphasis on innovation, it comes as no surprise to learn that R&D is a vital aspect of WAGO’s operations. Producing inventive solutions is at WAGO’s core and it considers itself a trailblazer. Repeatedly it has developed new products that have gone on to elevate the industry standard on the world market. This holds true for WAGO’s cage clamp connecting technology, push-wire connectors for junction boxes and the first fieldbus-independent, modular I/O system in the world. “R&D is carried out by the WAGO Group and it is extremely important – even in this year of strained resources the R&D budgets are increasing,” Leif reveals.

He continues, reflecting on the company’s qualities. “Our two product areas set us apart – the cage clamp and the automation part of our offering. We’re a small company in Norway with just 12 employees but we have really focused on the personal follow-up of our customers and on guaranteeing excellent service. We ensure that we grow, so that we’re always able to support our customers in day-to-day business – that’s a key issue for us. We want to ensure we’re maintaining close relationships with customers.”

With thoughts turning to the future, Leif discusses WAGO Norge’s objectives and reveals how he would like to see the business develop: “Even this year, with the global recession, we will increase our turnover compared to last. We’re enjoying a healthy business and I’m looking forward to keeping this up for years to come. We have already reached a healthy margin and we’re a little bit over half way regarding where we want to be as a company. We foresee healthy expansion in the next couple of years.”

WAGO Norge

Products: Spring clamp technology