Dorries Scharmann Technologie GmbH

Mean machines

Dorries Scharmann Technologie GmbH (DST) offers a wide range of machine tools for drilling, turning, boring, milling and grinding of medium and large size components.

Its product range includes, vertical turning lathes, horizontal machining centres, high-speed machining centres, portal machining centres and vertical grinding machines. Today, DST manufactures products for the brands Dörries, Droop and Rein, Scharmann and Berthiez. The company has sites based across the world, including Germany, France, the US, China, and the UK. With roots dating back over a century, the company has become internationally renowned for the production of high quality machine tools and is accredited to ISO 9001.

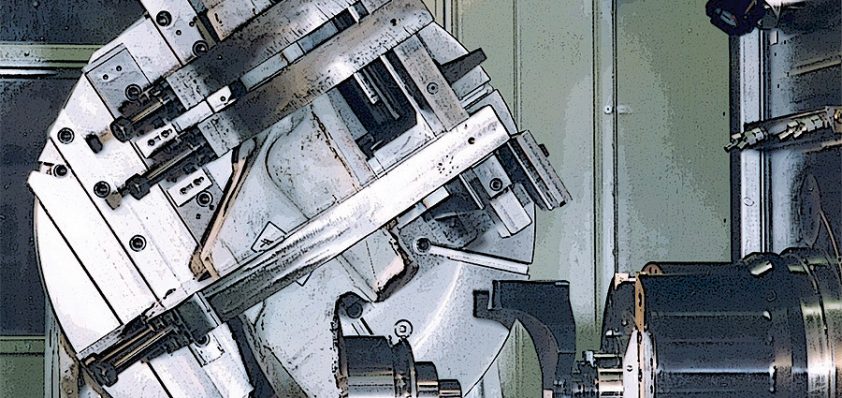

Ian Percival, sales director at DST explains: “Our main key strength is our technical innovation. We have been very active in the oil and gas industry for the past 20 years with our horizontal machining centres and vertical turning machines, and have delivered this equipment to most of the major oil and gas companies in the industry. We have been successful in doing this because of the outstanding technical features our machines have to offer. One example of this is a feature called a Facing Head, which gives milling machines the ability to turn. The Facing Head process is widely used in valve manufacturing and we have been a leading player in this technology for a long time, offering one of the best products on the market. Another of our strengths is to provide our  customers with vastly increased productivity and flexibility. We are also constantly trying to improve lead-times to be able to respond to our customers demands quicker.”

customers with vastly increased productivity and flexibility. We are also constantly trying to improve lead-times to be able to respond to our customers demands quicker.”

He continues: “We concentrate on application focused solutions, therefore we only make around 50 to 60 machines a year. In other words, if our clients are presented with a challenge and they need a product to help them overcome it, we will develop a process especially to their requirements. Due to this, we offer a wide range of products with the smallest having a work table of around 630 millimeters and the largest around ten to 12 metres.”

Ian adds: “Research and development is a key focus for us as we believe it gives us an edge over our competitors. As costs in general are a big challenge for all manufacturers we need to offer our customers more benefits over standard machines. The most important factors are productivity, flexibility and quality, which is what our customers have come to expect. We continually keep a close eye on their needs and do our best to follow them. One of the main demands of the market is to provide shorter delivery times. We are currently trying to reduce these by increasing stock of long lead-time items so we can react significantly quicker.”

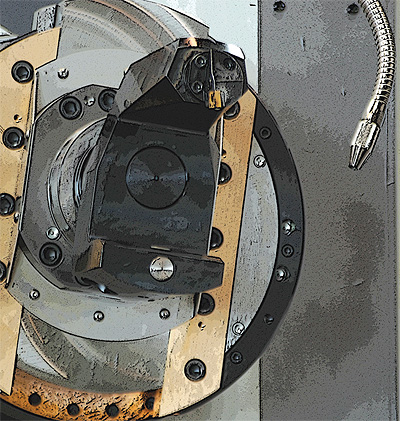

Through its extensive R&D, the company is constantly launching new products onto the market. Ian explains: “We have recently launched a new product for our Scharmann Horizontal machining centre programme, the DBF 630, which enables the machine to mill, drill, bore and turn all in one process. It’s the smallest product we’ve manufactured to date and has been targeted specifically at the valve industry in the oil and gas market.”

Before the introduction of new products, DST invests time and money into new machines, complex machine tools and flexible manufacturing systems. Furthermore, the company believes these can only be used competitively when all production areas are well prepared for the integration of such new machines. Therefore DST has its own training facility and wide variety of training courses.

Due to the increasing need for energy the industry is very buoyant at the moment, creating opportunities for any company working within it. Because of this DST is always looking for new markets to exploit. Ian elaborates: “We are currently working through representatives in Russia to look at potential growth there. We have already had some success in this area but the idea now is to open our own office to enable us to work closer to the market and keep an eye on potential contracts and projects.”

DST believes it is facing the future in a strong commercial position with a range of high tech products, which are finding markets with major international manufacturing companies. Ian concludes: “In the future we would like to maintain our position within the oil and gas industry, and hopefully increase it. The market at the moment is growing rapidly and this is reflected in our everyday business. Most of the energy resources that are yet to be recovered are either in deepwater or inhospitable areas therefore we can see opportunities for growth. The equipment used to access these areas is, sophisticated and the quality demands are very high. Due to this we are continually investing in our products and services to ensure we can meet any requirement. The main areas we plan to address in the future include the supply chain for the oil fields on the west coast of Africa, in Brazil and Malaysia.”

Dorries Scharmann Technologie GmbH

www.ds-technologie.de