Mohn Drilling

Hidden depths

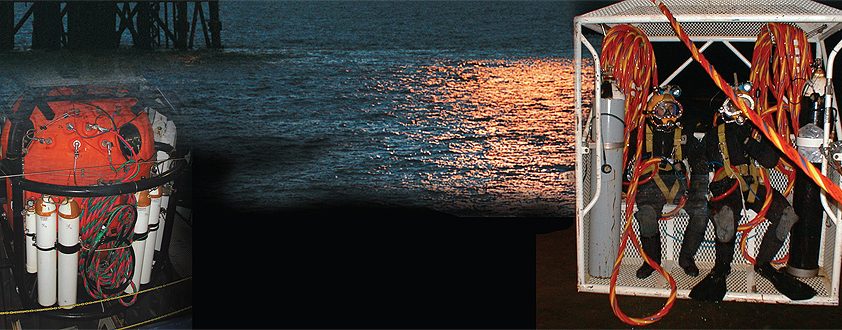

Established in 1985 by Stein Mohn, originally as a ship-owner and operator, Mohn Drilling has extensive experience in the offshore industry and a reputation for excellent service.

Based in Norway, the business offers a range of air and saturation diving services, and through its two subsidiary companies, Argus Remote Systems, and Artec Subsea, provides ROV (remotely operated vehicle) and survey services to customers around the world.

Stein Christian Mohn, a partner in Mohn Drilling elaborates: “Mohn Drilling provides air and saturation diving services. In addition to diving, the company has two subsidiaries, Argus Remote Systems and Artec Subsea, which focus on ROVs and associated tooling systems, and subsea survey operations, respectively.”

Mohn Drilling offers air and saturation diving services to customers with demanding requirements around the world, including a current major operation in Argentina: “We are presently operating on a ten year collaboration with DOF, off the coast of Argentina,” Stein explains. “We initially won the contract for diving and ROV services in 1999, and the newly built diving support vessel (DSV) Skandi Patagonia, started operations in December 2000.

“It is a year-round contract, in which we always have a minimum of five diving personnel on board,” he continues. “We have carried out saturation diving at the Aries and Carina field development,  where McDermot have installed new platforms. We completed the diving work related to this field, including tie-ins, free span correction and as-built surveys.”

where McDermot have installed new platforms. We completed the diving work related to this field, including tie-ins, free span correction and as-built surveys.”

Through its subsidiary company, Argus Remote Services, Mohn Drilling provides a range of high-quality, electric ROVs to customers, for rent, hire, and sales: “Mohn Drilling is the major shareholder of Argus Remote Systems, which is a business that specialises in subsea tele-robotics, and the development, design, manufacturing and operation of ultra-deep ROVs,” says Stein.

“Argus Remote Systems has 20 years of experience in the development of control systems for robots on land and in water, interface, power electronics, programming, and multiplexing hardware for signal transmission,” he continues. “All of the ROVs are manufactured in-house, using the Argus key components, which means that they are highly reliable, and that we are not dependant on external know-how for IRM or implementing improvements and customised changes.”

The company’s ROVs are used for a number of roles by a broad range of clients: “Argus rents and sells ROV services,” says Stein. Our clients include Nexans, EMGS, and many of the major oil companies. Additionally we work closely with the University of Bergen in a number of research roles, where we have completed subsea studies, including work in the mid-Atlantic mountain ridge.

“Our business concept is to use the clients’ vessels as a platform for our ROV operations, thereby lowering the operational costs,” he continues. “Our ROVs are capable of a broad range of roles, including construction, drill support, touchdown monitoring when cable laying, ROV survey with high-quality video, seismic vessel support, survey of cable routes, and survey with multi-beam, sidescan sonar and sub bottom profiler. We also do cable lays, not only power and fiberoptic cables, but also seismic ocean bottom cables.”

Included in the business’ catalogue of ROVs is its highly reliable Bathysaurus: “The Bathysaurus is an extremely reliable, ultra-deep rated, electrical work-class ROV,” says Stein. “It is depth rated to 6000msw, and since 2004 has proved very reliable at great depths. The machine operates regularly at depths between 1000 and 2500msw, without difficulties. It can still go much deeper.”

Stein is confident that electrical ROVs will continue to become more popular in the future: “We feel that electrical power, for continuous work, is the future of subsea operations. Electrical ROVs are extremely reliable, and due to the cold temperatures of seawater there is optimal cooling of the electrical engines and components. Additionally, electrical ROVs are lighter, and the dimensions make them more suitable for greater depths. Electric propulsion, as opposed to hydraulic, is also completely environmentally clean.”

Stein explains that the nature of the company’s diving operations ensures that safety is the primary consideration: “It is the key factor in all of our operations, we always think ‘safety first’. The health and safety of our divers is our number one priority, and together with our own company doctor, we have a contract with a diving medical specialist that is available 24 hours per day. We must also consider the environment that we are operating in. For example, Argentina is one of the most hostile environments in the world to dive in, due to low temperatures, strong tidal currents and the poor visibility.”

Looking to the future, Stein is confident that the company can continue to be highly successful: “I believe that the future looks very good for Mohn Drilling, and that the general demand for subsea and offshore services will continue to increase. The trend is towards exploring and operating deeper, and as our ROVs are depth rated to 6000 metres we are very confident that depth will not be an issue for us. We currently have three ultra-deep ROV spreads under construction, and will continue to expand in the future. In terms of diving, although we are a small organisation we are very efficient, and well equipped for the future. I believe that we can continue to grow at a very good rate for the coming years,” he concludes.

Mohn Drilling AS

www.argus-rs.no