Seaeye Marine Ltd

Extremely electrifying

When Ian Blamire decided he could provide a better service than was on offer, he established Seaeye Marine Ltd in 1986 with his wife to prove just that.

Seaeye specialises in the manufacture of electrically powered Remotely Operated Vehicles (ROV) for the offshore and oil and gas industry. Ian was aware that at that same time there were several manufacturers of small electric vehicles all capable of working in shallow water and for inshore applications, but none of these had proved a commercial success in the more demanding offshore market. Electric vehicles were known to suffer from a lack of power and long-term reliability problems particularly affecting their thrusters.

Matt Bates, the managing director of Seaeye Marine Ltd explains: “The challenge that Seaeye faced was to develop electric ROVs that could operate reliably in the offshore oil and gas industry,  particularly in areas with strong currents such as the Southern North Sea. The first ROV was the eyeball class Seaeye 600 which was to set new standards for power, performance and reliability. Lightweight composite materials were extensively used in the construction of the vehicle and a new thruster was developed with greater power and response than had been seen before. Over the years, we’ve designed more and more ROV models, continuously increasing their capability to meet the demands of our customers.”

particularly in areas with strong currents such as the Southern North Sea. The first ROV was the eyeball class Seaeye 600 which was to set new standards for power, performance and reliability. Lightweight composite materials were extensively used in the construction of the vehicle and a new thruster was developed with greater power and response than had been seen before. Over the years, we’ve designed more and more ROV models, continuously increasing their capability to meet the demands of our customers.”

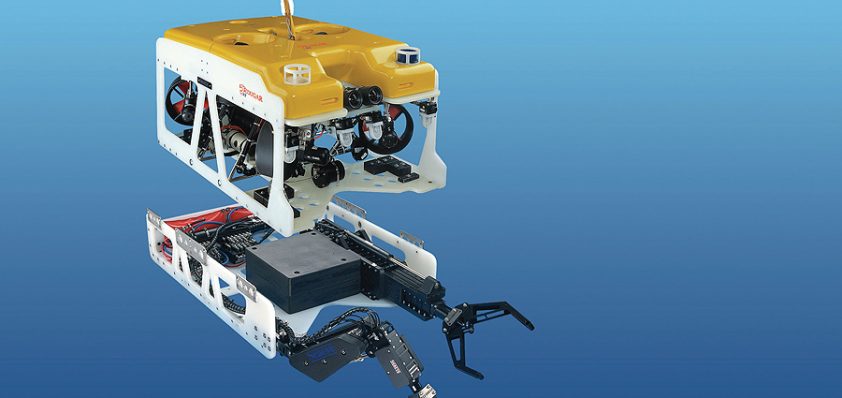

Seaeye now manufactures a complete range of electric powered ROV systems for all professional applications. The range currently extends from the portable Seaeye Falcon ROV to the medium work class Panther Plus ROV.

Matt comments: “All Seaeye’s ROVs can accommodate a standard range of tools and applications and we’re able to provide a customer design service for special tools and ROVs for any unique application. We also design and manufacture a range of ROV handling systems as well as a choice of Tether Management Systems (TMS), cameras, lights and subsea metal shell connectors.”

Focusing on the global oil and gas market, Seaeye has a worldwide client base – approximately 25 per cent of its products are supplied to the UK market, 35 per cent into the European market and the remaining 40 per cent are supplied to its clients based elsewhere in the world. Widely regarded since 1987 as the leading supplier of ROVs to the offshore and oil and gas industry, Seaeye now also supplies ROVs to a number of the world’s leading navies for submarine rescue, security, MCM, salvage and diver support tasks as well as to coastal and inshore operators for observation, inspection, environmental work, deep tunnel penetration and survey operations.

After 21 successful years, Matt highlights Seaeye’s key strengths: “We have delivered over 300 ROVs worldwide to date – a track record that gives our clients that extra confidence in us. The performance and reliability of our products as well as our after sales service and close relationship with our customers are what set us apart in the industry.”

Continuing, he elaborates on some of Seaeye’s products: “The Falcon is the smallest entry-level vehicle and is principally used outside the oil and gas market although it’s being used quite often as a portable fly-away system for inspection jobs in the O&G sector. This is an incredibly popular vehicle made in larger quantities mainly because it covers a wider market. As we go up in size, we also go up in capability; they become more powerful and able to carry more tools and sensors.

go up in capability; they become more powerful and able to carry more tools and sensors.

“The key issue I would like to highlight is how electric vehicles have developed over the years. When it all started for us, electric vehicles were only used for observation inspection type tasks but today, our electric vehicles go up to the half tonne, Panther Plus, which is capable of carrying lots of tooling. We also have the new Cougar XT, which has got even more capabilities than its predecessors. Electric vehicles always had the initial reputation for only being good for inspection work but today they’re carrying out a massive range of subsea work tasks as well.

“Steadily electric vehicles are getting more capable, and more cost-effective with the increasing need to go deeper as oil and gas need to be extracted from deeper places,” says Matt. “We’re constantly finding that the tasks and applications demanded by the customer are becoming increasingly complex and difficult, but this only keeps us on our toes. What we’re doing, as well as going deeper, is increasing the range of tooling they can carry and developing new tools. These are the essential developments – more capable and deeper. There are also a lot of smarter sensors and tools being launched and we need to be able to integrate those and work with suppliers and manufacturers to come up with a complete solution.”

Moving on, Matt comments on Seaeye’s most recent launch: “We’ve had the Cougar for a number of years but we recently launched the Cougar XT, which is basically a turbo charged version. We’ve doubled the power and increased the vehicle’s thrust by over 50 per cent so it now has the highest thrust to weight ratio of any vehicle in the same class. What this basically means is that you’re able to carry more tooling and more sensors than a vehicle of the same size, and be able to do more with the vehicle without affecting its performance. This was principally designed because customers want to work in increasingly extreme conditions and work longer through currents while carrying all this tooling.”

With his thoughts on the future, Matt adds: “The oil industry is very strong and buoyant and we’re extremely busy right now but we are also constantly looking to grow into new markets and new applications – there’s a lot of scope for these vehicles to do a wide range of tasks. The toughest thing right now is keeping up with the demand from existing work while trying to also keep up with the demands for new developments.”

He concludes: “We’re going to remain very focused on continual development, constantly updating our range as new technologies and new requirements come along, and as a result continue increasing the capabilities of our electric ROVs.”

Seaeye Marine Ltd

www.seaeye.co.uk