Strategic Biofuels

Fuels for the future

From residual wood waste to carbon negative renewable diesel, Strategic Biofuels details the pioneering process it’s using to singlehandedly shake up the fuel industry

By developing a series of carbon negative and clean-burning renewable transportation fuels from responsibly managed and sustainable forest waste, Strategic Biofuels has undoubtedly become the leader of its industry niche. The company was founded in the summer of 2020, making it a decidedly positive pandemic progeny, and has since brought together an expert team of highly experienced individuals with petrochemical, synthetic fuels, renewable fuels, and oil and gas backgrounds.

Though the pandemic proved to be an impediment to many companies, Strategic Biofuels is an impressive exception. The company continues to offer value to the environment and the communities where it works, reducing greenhouse gas emissions by 400 percent (compared to fuel production from fossil fuel-derived sources). Such a staggering figure is attainable by doing two things: firstly, producing deeply negative carbon footprint drop-in fuels from non-food-based biomass materials so that the fuel can be used at 100 percent (unlike biodiesel); secondly, utilizing carbon capture and sequestration technology to dramatically reduce CO2 emissions by safely and securely storing the greenhouse gas deep underground.

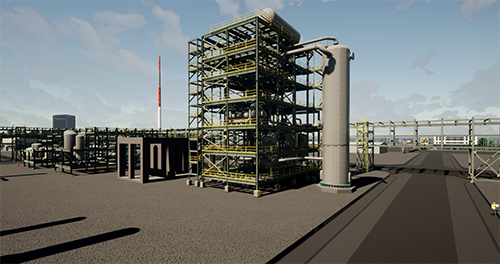

These two processes also represent the fundamental tenets underpinning the new Louisiana Green Fuels Project (LGF), which is currently being constructed on a 300-acre site at the Port of Columbia in Caldwell Parish, Louisiana. By following these two core processes, as well as a host of other pioneering methods, the plant will achieve better than Net Zero emissions and remove more carbon from the environment than it produces. Proudly talking us through the landmark project, and the ground-breaking processes behind it, is Dr. Paul F. Schubert, CEO at Strategic Biofuels.

These two processes also represent the fundamental tenets underpinning the new Louisiana Green Fuels Project (LGF), which is currently being constructed on a 300-acre site at the Port of Columbia in Caldwell Parish, Louisiana. By following these two core processes, as well as a host of other pioneering methods, the plant will achieve better than Net Zero emissions and remove more carbon from the environment than it produces. Proudly talking us through the landmark project, and the ground-breaking processes behind it, is Dr. Paul F. Schubert, CEO at Strategic Biofuels.

“In total, LGF will produce approximately 33 million gallons of renewable fuel each year,” he begins. “When broken down, that equates to about 87 percent renewable diesel and 13 percent renewable naphtha. This fuel will have the lowest carbon footprint of any liquid fuel; it represents almost a 400 percent reduction in greenhouse gas emissions when compared to its fossil fuel-production equivalents. Indeed, while the carbon intensity of our fuel has been scored by Life Cycle Associates at -294 gCO2e/MJ, fossil diesel is usually scored much higher, at around +100 gCO2e/MJ. In simpler terms, the carbon intensity of the renewable diesel we produce is extremely negative. In fact, it’s the lowest carbon intensity fuel in the world.”

Strategic Biofuels has secured more than $42 million in funding for LGF thus far, including a $15 million infrastructure improvement grant from the State of Louisiana to the Port, and will generate a total of 85.5 MW of biopower when fully operational. All of the power that LGF needs will be produced on-site through the conversion of a sawmill feedstock, which is garnered from waste generated by the lumber industry. This power will not only produce renewable fuels. It will also provide the amount of energy needed for carbon capture and the compression of the CO2 for sequestration.

As Paul explains, carbon capture and sequestration are critical carbon mitigation methods, which, in turn, will be responsible for helping LGF achieve Net Zero status. “Strategic Biofuels has selected Louisiana as the location for its landmark project for several reasons, with one of them being the fact that Louisiana has the necessary geology to facilitate sequestration: the process in which CO2 produced alongside the making of renewable diesel is locked about a mile underground, where the same forces that have held oil and gas beneath the earth’s surface for millions of years will trap the CO2 forever.

“The sequestration is the dominant element creating the negative carbon intensity of LGF’s fuel,” he adds. “Louisiana has a visionary legislative and regulatory framework that supports carbon sequestration. This includes defining that the surface owner holds the right to inject CO2 beneath their land under so called ‘pore rights.’ There is an eminent domain right for a sanctioned project to acquire those pore rights from individuals, meaning that no owners can block the project. Furthermore, after the project ceases CO2 injection and has validated that the locked-in greenhouse gas is secure, the state has created a fund to monitor and remediate the CO2 storage – those funds will come from the initial operating revenues of the facility. We expect to sequester roughly 1.4 million tonnes of CO2 per year.”

For Paul, the most important part of the project was completing the sequestration test well in the first half of 2021. The company recognized that the project’s economics all depended on this one test as it would demonstrate whether LFG’s geological foundations were, in fact, tenable. “The effort could’ve failed, and investors could’ve lost their money,” says Paul. “In our case, however, the sequestration test well was a complete success. The combination of our technology set and its use at scale is unprecedented. The technologies used in the plant are not new; they’re all well-established. However, it’s their new configuration, as applied at LGF, which makes them unique.

“We are using gasification and partial oxidation to produce syngas (CO plus hydrogen) from a solid, carbon containing feedstock,” he details. “This is followed by hydrocarbon synthesis via the Fischer-Tropsch process to make paraffinic wax and oil, which are then hydrocracked using standard refinery technologies. These technologies have been utilized at a commercial scale with coal (a much more difficult feedstock) since at least the 1950s. At LGF, though, we make the process unique by combining carbon capture and sequestration techniques with a non-food-based biomass feedstock.”

Since we’ve covered the former, let’s now turn to the latter: the non-food-based biomass at the metaphorical heart of the industrial process. By utilizing pre-commercial thinnings – that is, excess trees taken from sustainable forestry plantations, which have been removed to allow the natural maturation of more dominant trees – Strategic Biofuels has ensured that its fuel feedstock is sustainable on multiple fronts.

“First, it creates a new use for from forestry byproducts, improving economic returns in the timber industry,” explains Paul. “Second, since thinnings are non-food based and overly abundant, the feedstock doesn’t compete with food production and hence maintains food security. Unlike other crops, thinnings are produced all year. The amount of renewable fuel that can be produced per acre per year from thinnings is about 497 gallons, with a feedstock cost of about $0.53 per gallon of renewable fuel. Whereas, in contrast, soybeans yield about 53 gallons per acre per year, with a feedstock cost of about $6.00 per gallon. Soybeans also compete for the allocation of arable land which would otherwise be used for growing food.

“The ultimate result of this process is an extremely high-performance synthetic diesel,” he adds. “Just like synthetic motor oil is superior to traditional motor oil, our synthetic diesel is superior to traditional diesel: it has a much higher cetane (the measure for diesel like octane is for gasoline), creates lower engine emissions with essentially zero sulfur, and is both non-toxic and biodegradable. Biodiesel is severely limited in terms of the amount which can be blended into diesel fuel; conversely, our renewable diesel can be used in any concentration – including 100 percent. All this makes it truly sustainable.”

However, sustainability does not refer to solely environmental factors. In fact, sustainability is a broad, wide-ranging term that also involves social and economic issues. Let’s zero in on LGF’s contribution to these two aspects of sustainability. The renewable fuels facility is, for instance, being built in the seventh poorest Congressional District (LA-5) in the US. In that region, the average household income is $36,000 per year, compared to a national average of $97,026.

“The first phase of the plant will create about 900 full-time jobs,” observes Paul. “The direct employment of the plant, once operational, is expected to generate 150 full-time positions, with an average salary of $69,000. However, indirectly, more than 750 full-time jobs will be created. Indeed, over the plant’s 31-month build schedule, the number of construction jobs available will peak at 1500. Once plant expansions in Caldwell Parish are completed, we’re also expecting to create about 600 direct and nearly 3000 indirect jobs. Needless to say, our project in Caldwell Parish will have a highly positive economic impact on the region.” In fact, LGF has already received a Community Impact Award from Trade & Industry Development Magazine as part of its 2022 CICI Awards.

“Our engineering partner, Hatch, has also started a STEM (science, technology, engineering, and math) program in Caldwell Parish schools,” he continues. “Hatch engineers will provide mentoring to local students for their robotics competitions. This provides an unprecedented opportunity for the students in this poor community. Exposure to Hatch’s program, which is being committed to by the company for at least three years, will create vital opportunities for international interactions.”

As Paul has made clear, the work being carried out in Caldwell Parish, Louisiana is not only groundbreaking – it’s truly sustainable, and in more ways than one. Over the next 10-to-12 years, Strategic Biofuels intends to grow, carrying out a three-phase expansion that will create new job opportunities and increase LGF’s production levels. Currently in phase one, the new plant is expected to make around 33 million gallons per year; however, Strategic Biofuels aims to incrementally increase its output, ultimately leading to its remarkable third phase, where a staggering 161 million gallons of renewable diesel will be produced each year. For LGF and its surrounding region, then, exciting and sustainable times are certainly ahead.

Strategic Biofuels

https://strategicbiofuels.com

Products: Renewable fuels