Zeta-pdm Ltd

A standout solution

Founded during January 2000, Zeta-pdm has 15 years of industry experience as a world leader in separation processes and a key supplier of advanced technology to the oil, gas, water and petrochemical industries. Its successfully completed projects include new-build and revamp projects, covering onshore and offshore applications, which are delivered with a principle aim to deliver tangible benefits to clients by reducing the times between the initial enquiry, submission of a proposal and the final delivery of the equipment. Presently Zeta-pdm employs 22 members of staff across its offices in Newport, and Aberdeen within the UK, as well as Arnhem in the Netherlands. Furthermore the company maintains an office in Malaysia and close contacts with agents in Abu Dhabi, Qatar, and Korea.

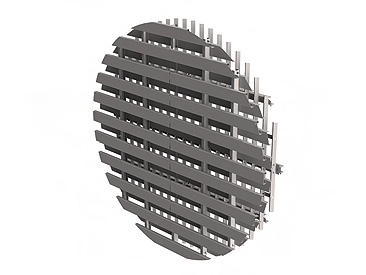

Zeta-pdm is a specialist technology supplier to the oil, gas, water and petrochemical industries. Services include consultancy, revamp and new build equipment for Production and Test separators, gas scrubbers, gas knock-out drums, slug catchers, produced water degassers, flash drums, flare knock-out drums, and enhanced oil recovery systems. Zeta-pdm delivers practical and credible engineering, process design expertise and solutions, based on the extensive range of ‘state-of-the-art’ internals technology encompassing; inlet devices, such as its ZP-4G® Inlet Cyclones, ZSQ® and its various vane types; distribution devices, including ZHB®, ZVB®, ZSB and ZPC fluid control technology, perforated baffles and bespoke configurations; liquid-liquid coalescers and; gas-liquid demisting and coalescing devices comprised of mesh type and vane type coalescers and demisting devices and 4G-FD® Demisting Cyclones. Furthermore, the company offers a comprehensive range of defoaming and sand removal equipment.

Key to the success of Zeta-pdm is the long-standing relationships that the company maintains with its suppliers and fabricators that enable the company to ensure that the product solutions it provides achieve a uniform and high level of quality in terms of both design and manufacture. “One of Zeta-pdm’s key points of focus is the relationship that is built between the client and operations team. We pride ourselves on offering well thought out and delivered solutions to our clients. Getting contracts delivered on time and on budget requires a great deal of understanding, experience and attention to detail. We work closely with our clients to make sure that we not only meet all their requirements but that we also offer advice and assistance to smooth the whole process. The excellent feedback we get from our clients proves we are getting this mix just about right. We have long-term and close-knit relationships with the fabricators that we use specifically for our products,” explains Operations Director, Nigal Peach. “We have a complete range of products that will cater for anything required for the separation process within the pressure vessels themselves. Process design is carried out for each vessel which will identify the required products, these products will then be engineered specifically for the target vessel – we don’t have an off-the-shelf product.”

Currently the majority of the company’s business is derived from the North Sea sector; however Zeta-pdm is also active within Asia and the Middle East. In recent months the company has enjoyed a significant increase in demand for its range of services and the supply of its specialist equipment to an ever expanding portfolio of clients across the globe; currently Zeta-pdm is involved with several contracts totalling upwards of £2 million. Furthermore Zeta-pdm has also seen increased orders relating to its consultancy services, including Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA). “We are extremely pleased to have enjoyed a strong period of growth in the current difficult climate. However, we continue to invest and strengthen our operations across the globe through supplying support and front-end engineering, together with bespoke equipment solutions and equipment, to a prestigious client list,” comments Managing Director, Stephen Turner. “In recent years, we have worked hard to become established as one of the leading providers of tailored solutions and separation internals and it’s clear that we are now reaping the rewards of our efforts. We understand, however, that it is essential we continue to capitalise on the many opportunities opening up for us and focus on forming and harnessing relationships with our various international partners.”

Throughout the closing months of 2015, Zeta-pdm will seek to continue to build on its current success while further exploring new opportunities both domestically and abroad. “We have an exemplary record in terms of the operation of our equipment and its longevity, which is important to our clients. Everything is designed and fabricated within the UK, so the standard we produce is remarkably high even in a very demanding industry,” concludes Director Norman Arnold. “Over the coming years we naturally intend to maintain our strong market presence in our traditional markets, however we will also look to expand into new markets such as North and South America. The US in particular represents a different market to what we are used to, as buyers there tend to prefer to buy an off-the-shelf solution rather than the high-tech approach that we provide, however we certainly see this as an exciting opportunity.”

Zeta-pdm Ltd

Services: Separation process technology