Recycling and Safety in Focus: The Oil and Gas Industry’s Pursuit of Responsible Waste Management

On the recycling path

In the oil and gas industry, together with a number of other markets, the safe disposal and recycling of industrial waste products is a highly important issue.

In applications such as natural gas production the raw materials and accompanying waste can contain radioactive elements and mercury contamination, which can prove very dangerous. Taking the lead in overcoming this problem, Siempelkamp Nukleartechnik has developed a suitable technology to separate harmful substances from the useable metal, thereby recycling harmful scrap.

Siempelkamp Nukleartechnik’s experience in the disposal of nuclear waste has meant that taking the technology into the oil and gas sector has been reasonably simple. Ulrich Quade, vice president  recycling at the business, explains: “In the 1960s Siempelkamp began supporting the nuclear industry with its large foundry facilities by casting shielding products for various applications – including a biological shield for the first ever German nuclear powered ship. In subsequent years these activities continued, expanding to the production of such items as cast-iron transport and storage containers for spent nuclear fuel.

recycling at the business, explains: “In the 1960s Siempelkamp began supporting the nuclear industry with its large foundry facilities by casting shielding products for various applications – including a biological shield for the first ever German nuclear powered ship. In subsequent years these activities continued, expanding to the production of such items as cast-iron transport and storage containers for spent nuclear fuel.

“During the 1980s we developed a highly efficient melting process to dispose of and recycle the radioactively contaminated metals from the nuclear facilities and operations, to be used in new applications,” he continues. “During the mid-1990s we were approached by members of the oil and gas industry, the first of which was an East German company that had a lot of waste, including tubes that had varying degrees of radioactivity in them. They were well aware of our experience in the disposal of nuclear material and wanted to know if we could recycle and get rid of the tubes.”

At the time it was not commonly known that raw materials from oil and gas operations, particularly mineral oil and natural gas extraction facilities, are contaminated with radium and thorium.

Ulrich explains that in the initial investigation into the possibilities of recycling oil and gas waste, a number of other concerns were encountered: “When analysing the feasibility of this we found that together with the radioactive properties of the waste, mercury would also be present. As mercury completely evaporates at high melting temperatures the furnace for recycling oil and gas waste would need an effective exhaust and combined air filter system to retain the mercury vapour from the off-gas. As a consequence, in 1998 we decided to develop a specially licensed melting furnace specifically for the oil and gas industry, to melt NORM and mercury contaminated steel scrap.”

This large-scale plant, known as GERTA, is fully licensed in accordance to German federal laws on air pollution and has an annual melting rate of 2000 Mg. The success of the initial operations has led Siempelkamp to be approached by a number of leading organisations in the oil and gas field. Ulrich elaborates: “The market is looking very good at the moment, and our order books are full for the next three years. At present, we have a large number of clients in the North Sea area offshore and on-shore, having completed work for Exxon, Shell, Conoco, Wintershall and Aker Kvaerner, and have recently been approached by British Petroleum.”

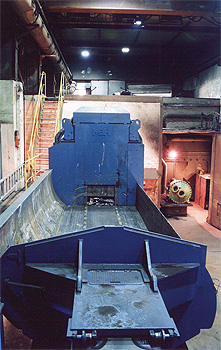

Ulrich expands on the capabilities of the GERTA plant, and the factors involved in a recycling operation: “We have the waste material shipped directly to the plant, where it is sent to a cutting and dismantling area that uses a guillotine shear with cutting power of up to 650 tonnes to cut the components to smaller sizes. After this cutting, we sort the material and send it to one of three large storage bunkers depending upon type, size and kind of contamination, before it is sent to the furnace.

storage bunkers depending upon type, size and kind of contamination, before it is sent to the furnace.

“The furnace itself is an electric induction type with a capacity of eight tonnes,” he continues. “It is charged using a mobile charging system that is loaded outside and then moved into the furnace by a lock that connects to the furnace hood by a leak-proof adaptor. During melting, all of the air extracted from the process is purified in a multi-stage filter system that has a cyclone, and air cooler and filter, which allows us to cover the mercury and other impurities. The extracted air is continuously controlled and analysed for mercury and radioactivity levels.”

As part of the process all of the material that is not contaminated can be put to very effective use, as Ulrich explains: “After melting we produce one tonne blocks of material that are free from contamination and can be sold straight to the recycling market. It really is a very efficient, environmentally friendly process that makes the most of this industry scrap.

“Even the waste from the melting process can be put to very good use,” he continues. “This consists of slags that have some radioactivity but have been deemed to be safe through expert analysis, and these can be recycled for various construction uses in Germany if the contamination levels are below the regulation amounts. Most commonly, our slags are used in road construction activities on landfill sites. Filterdust containing mercury is conditioned and disposed of in an underground depository in Germany.”

Happy with the reception that the recycling service has seen in the oil and gas field, Ulrich is confident of further success for the business: “We are very interested in expanding in the offshore market when and where the opportunities become available. As mentioned, we are fully booked for the coming years, but I think that as companies realise what we can offer that we will be able to expand our capacity here in Germany, together with looking at possible partnerships in the UK.

“Siempelkamp is a very progressive, expansive company – in all of the fields that it operates in. My overall vision is that if the oil and gas market continues to expand as we expect, we will be able to run a separate organisation dedicated to the recycling and de-contamination needs of that industry,” he concludes.

Siempelkamp Nukleartechnik

Services: Waste recycling and disposal