SBM Offshore: Leading Innovator in Offshore Oil Solutions

Deepwater developments

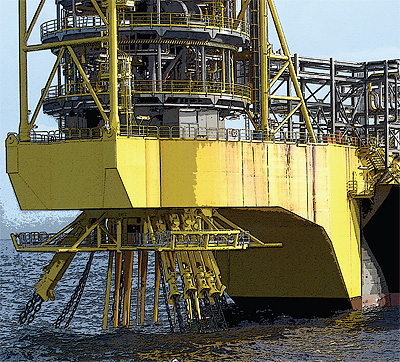

SBM Offshore N.V, which comprises of a group of international subsidiaries, is a leading supplier to the global offshore oil and gas industry.

The company, which has a strong combined history in the maritime sector, currently provides a broad range of products and services that includes offshore oil and gas FPSOs and FSOs, offshore import/export terminals, and offshore construction and installation contracting services. Through the years the business has been a leader in offshore innovation, maintaining the tradition of its vision – ‘Technology Creating Value’.

SBM’s history can be traced as far back as 1965 and the creation of the N.V. Industrieele Handels Combinatie Holland (IHC) – which loosely translates to the Industrial Trading Combination of Holland. This comprised of a number of important local shipyards and shipbuilders with much experience in the industry, including Gusto in Schiedam, Smit in Kinderdijk, and Verschure in  Amsterdam, all of which focused on the engineering and construction of specialised vessels. However, these yards had already began to move into the offshore oil and gas market, with Gusto constructing the first single point mooring (SPM) facility under a license agreement with Shell in 1959.

Amsterdam, all of which focused on the engineering and construction of specialised vessels. However, these yards had already began to move into the offshore oil and gas market, with Gusto constructing the first single point mooring (SPM) facility under a license agreement with Shell in 1959.

As the market for these SPM systems developed rapidly the decision was taken in 1969 by IHC to create a separate business to market and further develop the products – Single Buoy Moorings Inc., or SBM. The European shipbuilding crisis of the 1970s meant that many of the shipyards incorporated in IHC were closed, with a large proportion of the engineering capabilities and experienced employees becoming active with SBM in subsequent years. During the 1980s and 1990s the product line of SBM expanded, embracing complex mooring systems for FSO and FPSOs and rapidly establishing itself as a market leader in the field. Following further expansion, and the merging of a number of other associated organisations, SBM Offshore was created in 2005.

Elaborating on this, Sebastiaan de Ronde Bresser, investor relations officer at SBM comments on the company’s current role within the global offshore industry: “SBM Offshore designs, develops and constructs floating production platforms and associated equipment, specialising in FPSOs, which essentially are tankers converted for special use. We carry out all of the engineering and design for the units together with the execution, but sub-contract all of the construction to specialised third parties in a number of areas around the world, including Dubai and Singapore. Here, our modules are fabricated and integrated onto the deck of a new FPSO, before being pre-commissioned for operational use. Our most recent unit was manufactured in the MMHE shipyard in Malaysia for local operational use with Petronas.”

SBM Offshore operates through a number of dedicated facilities located in key areas around the globe: “We undertake our projects at four execution centres around the world,” says Sebastiaan. “We have around 900 people operating at our site in Monaco, which is the headquarters of the company where the board of managers sits, and is where the lease fleet is managed from. We also have facilities in Schiedam in Holland, Houston and Kuala Lumpur, where we have been recently building another state-of-the-art execution centre. Each of these sites specialises in a certain core skill or technology, and our strategy is that each expertise that is available in one site can be easily and quickly transferred to another if needed. For example, at Monaco we specialise in mooring systems, whilst in Schiedam we are very strong in naval architecture. However, each project has access to specialised knowledge independent of location.”

Sebastiaan believes that this flexibility is one of the key strengths of the business: “All of our employees are very flexible, and it is normal for them to move around our facilities and operations regularly to keep them fresh. This combined with the wealth of knowledge that is available among our personnel, means that they can move into new developments very easily, and certainly gives us a competitive edge. Another advantage that we have is that as we operate units out of our own lease fleet we are in an ideal position to get a lot of useful feedback for clients regarding the operations and integrate that into new systems. For example, when we carry out our regular design reviews we invite our key clients and operators to the meetings so that they can offer valuable information to the overall development process.”

The company both leases and sells its FPSO and FSO designs to many of the industry’s leading names: “We supply our complete units or moorings systems to a number of important customers,  including Petrobras, Exxon Mobil, Shell, BP, Chevron, and Total, both through lease contracts and sales. Our lease contracts are for a fixed period of usually between six and 15 years, with an option for an extension of this afterwards. The contract designates a fixed-day rate for each unit before the project starts, as there is no spot unit for FPSO day rates in the industry. Furthermore, we never build an FPSO on speculation. We target the complex FPSO market building units that are predominantly field-specific, which means that we only build when a contract is in hand.”

including Petrobras, Exxon Mobil, Shell, BP, Chevron, and Total, both through lease contracts and sales. Our lease contracts are for a fixed period of usually between six and 15 years, with an option for an extension of this afterwards. The contract designates a fixed-day rate for each unit before the project starts, as there is no spot unit for FPSO day rates in the industry. Furthermore, we never build an FPSO on speculation. We target the complex FPSO market building units that are predominantly field-specific, which means that we only build when a contract is in hand.”

SBM Offshore places considerable emphasis on customer service, and together with tailoring its lease contracts to best suit an individual client’s needs, it operates its own installation vessel: “The Dynamic Installer is an ultra-deep water installation vessel, which we own, giving us a competitive commercial advantage,” Sebastiaan explains. “Building an FPSO can take up to three years, which means that it is very difficult for us to give a customer an accurate estimate for installation costs. Rather than take a gamble, we know that we always have the option to carry out an installation ourselves, which is certainly an important asset to have.”

Today, SBM’s activities encompasses a broad scope of offshore solutions based around the engineering, supply and offshore installation of SPM systems used in the offshore loading and unloading of tankers or the permanent mooring of offshore oil production and storage vessels. Predominantly it designs and supplies turnkey FPSO and FSO units, together with tension leg platforms (TLPs), floating production units (FPU), and self-elevating mobile offshore production units (MOPUs). The company is well known as one of the pioneers of FPSO lease contract operations, having 15 units in operation at the end of 2006, with a further four under construction.

Most recently the business has signed a new contract with Petrobras for the turnkey supply of its P-57 FPSO, which will be installed on the Jubarte field offshore Brazil. Signed in February 2008, the contract represents a portfolio value of $1.25 billion inclusive of three years operating services, Importantly, the contract represents a major step forward for SBM as the P-57 FPSO is a larger unit than any previously supplied, and will have the capacity to produce 180,000 barrels of oil per day with total gas compression of 71 MMscfd. The FPSO, which will most probably be converted in Singapore, will be delivered at the end of 2010.

Much of SBM’s phenomenal success in the industry is based on its continuous focus on development and introducing innovative solutions to oil and gas customers. Sebastiaan looks at some recent projects: “Our slogan is ‘Technology Creating Value’, and this underpins all that we do as a company. Our strongest factor has always been developing solutions that offer considerable advantages over previous technology for our clients – particularly to allow them to explore and produce more cheaply and efficiently.

“One of our most recent, and most innovative developments is the design of a liquefied natural gas (LNG) FPSO for producing and storing LNG offshore,” he continues. “The project is only on the drawing board stage at present but it will enable oil and gas clients to successfully produce the large majority of the stranded offshore gas fields in difficult regions. Currently a number of these fields remain stranded as they are either too far from the shore, or there is no market demand near enough to them to be profitable. The only option for true field use is to develop an FPSO, so that the gas can be produced efficiently offshore.

“As LNG is a relatively new area for us we have formed a partnership with Linde AG, a German company that is well known in the gas development sector, particularly for LNG operations,” says Sebastiaan. “They already have a proven LNG production process which is suitable for fitting onboard an FPSO. The storage size and deck space requirements mean that we have to build an entirely new hull to compensate for the extra requirements in weight. We are very pleased with the development capability of the concept and there is already a great deal of interest from a number of clients, which means that within a year we believe we will have a contract for an LNG vessel.”

The company’s developmental foresight does not stop there – it has also been working on new solutions in other areas: “Within the more traditional offshore oil sector we have developed semi-submersible production units and mobile offshore production units (MOPU), primarily in order to expand our geographical presence and to offer a wider product catalogue. The MOPU design is a jack up type of production unit with storage, which we first started two to three years ago, and has already been successful.

“Additionally, we have produced a range of products that allow the tie-in of satellite fields situated in deep waters,” he continues.“One of the biggest issues when pumping product through pipelines in deep waters is that the temperature is so low that flow problems occur. Our solution uses a gravity-actuated pipe (GAP), which stays close to the surface thus eliminating pressure and temperature flow problems, and allowing the client to tie in the main producing site with the satellite fields in deep water.”

Addressing the coming years, SBM Offshore has established a target of average double-digit growth, whilst being consistently at the forefront of technological development for innovative solutions that reinforce its leading position in the world market. Its current product line is diverse enough to meet the expected demands of oil and gas exploration, with new solutions such as the LNG FPSOs looking certain to open new, niche areas for the company. Over the next five-year period the business intends to develop innovative technical solutions, to continue to be at the forefront of offshore deepwater technology, to cultivate a quality and reliable service, and to focus on marketing strategies to create partnerships with other industry leaders.

Looking to the future, Sebastiaan believes that the wealth of exploration opportunities available in the global market means that SBM Offshore faces exciting prospects: “There is an enormous amount of exploration and production drilling offshore today, and every new find is a potential FPSO development because in deep water floating production units are the only way to develop deepwater fields. We have an excellent product and core of expertise, together with a good reputation, and we hope to expand our fleet by a minimum of two units per year, whilst continuing to grow the business in the market,” he concludes.

SBM Offshore

Products FPSO development