The history of VSMPO Titan Ukraine dates back to the mid 1930s when a small tube-rolling mill shop began work

Titanic undertakings

This is considered by those within the industry to be the official founding date of Nikopol Yuzhnotrubniy Zavod, soon to be Europe’s largest industrial enterprise. By 1955 its tube shop No. 5 was the main producer of seamless cold-finished tubes, made from titanium and titanium alloys, in the whole of the USSR. Following a number of changes in identity between 1990 and 2009, mainly due to acquisitions, December 2009 marked the renaming of the manufacturing enterprise to its current title. As part of JSC Corporation VSMPO-AVISMA, it is today a global manufacturer and producer of seamless titanium tubes and pipes, primarily sourced out to the oil, gas and petrochemical industries, with clients in the US, Asia and Europe.

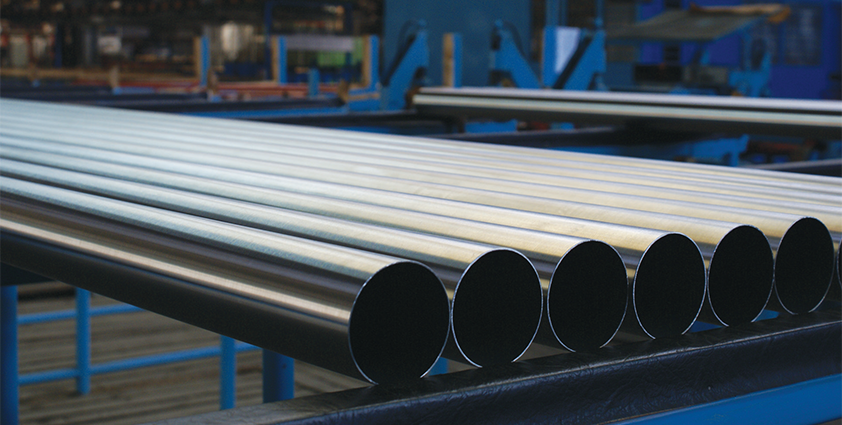

“Our titanium tubes and pipes are used across the oil and gas industry, in the production of natural gas liquids, chemical and petrochemical processing and high pressure leaching of copper, nickel and gold ores,” explains Kostyantin Antonov, chief executive officer of VSMPO Titan Ukraine. “We have participated in several projects under Pemex, Qatar Gas, Maersk Qatar and Exxon Neftegas Ltd in the last four years.

“We offer all of our customers a wide range of products in various alloys, standards and sizes and our seamless tubes can be fabricated from Russian or international alloys. Our material is sold to industrial markets such as the oil and gas industries and used in a number of applications. Our seamless tubes fit for LNG vessels, FPSO topside modules, firewater systems and offshore platforms. Besides, titanium tubings are widely used in the Russian market for chemical and shipbuilding, nuclear and aerospace industries.”

Employing over 600 staff and with a large client base, the facilities used to manufacture and produce VSMPO Titan Ukraine’s products are the envy of others within the market, its facility in the Ukraine is in fact the largest of its kind in the country. As Kostyantin reveals, the company is always looking to modernise: “We always try to develop and make changes to facilities, equipment, tools and our production range to meet market demands. Our development and investments programme is approved to run into 2015 and we will continue to fulfil our commitment to this. The most recent change in our workshop is the installation and start up of a new KPW mill that will allow us to increase our capacities twice”.

Business is progressing at a fast pace in the first half of 2011 as Kostyantin points out: “We are now finishing an oil and gas application order for the Arkutun-Dagi platform. The field is located off the northeast coast of Sakhalin Island in the Russian Far East and will become the first ExxonMobil-operated platform with friction pendulum bearing isolators. Its topside will be among the largest in the industry, weighing some 28,000 tonnes, and through this pipe order Uniti Titanium has gained vendor approval from ExxonMobil and expects more orders for topside modules and firewater systems in the future.”

Business is progressing at a fast pace in the first half of 2011 as Kostyantin points out: “We are now finishing an oil and gas application order for the Arkutun-Dagi platform. The field is located off the northeast coast of Sakhalin Island in the Russian Far East and will become the first ExxonMobil-operated platform with friction pendulum bearing isolators. Its topside will be among the largest in the industry, weighing some 28,000 tonnes, and through this pipe order Uniti Titanium has gained vendor approval from ExxonMobil and expects more orders for topside modules and firewater systems in the future.”

Among other large projects the company is undertaking the fabrication of tubing for the Kuwait National Petroleum Company project Fourth Gas LPG Train with construction due to start in April 2011 and completion scheduled for late 2013. Additionally, in January of this year it completed the last shipment of the largest order of seamless titanium tubes in history, contracted by TSM Tech Co. to be used in the fabrication of heat exchanges.

In the opinion of Kostyantin there is still plenty of opportunities to grow in the current market: “The market is definitely picking up and we anticipate it to remain strong for the next few years with customer demands growing. Titanium is a sustainable solution for corrosion problems across a wide range of industries and this is the reason we expect the market to continue expanding. Within the next three to five years we will increase brand recognition and we see our company participating in many large projects within the industry hopefully with some of the biggest names in the business.”

Having recently expanded its workforce for the expected production increase and with new products currently in development, the reasons for VSMPO Titan Ukraine’s success are clear. As Kostyantin enthuses: “Our key strengths are the exclusiveness of our materials, the special properties they feature, our wide production range and our expert technical capabilities that allow us to meet any customer’s demands. We are partners with two of the world’s largest integrated titanium producers and have the broadest range of sizes and grade capability in the industry. These facts and our superior in-house technology and metallurgical expertise truly sets us apart from others in the industry.”

VSMPO Titan Ukraine Ltd

Products: Manufacture and production of titanium tubes and pipes