Flowplant Group

Go with the flow

Synonymous with the brand name ‘Harben’, Flowplant Group has been manufacturing pumps and related high-pressure water jetting equipment, from its facility in Wiltshire, UK, since 1971.

In 1998 the business was sold by its parent plc to the then management team, a move that also saw Flowplant subsequently boost its portfolio with the acquisition of the ‘Aqua’ pump range. Current managing director, Mark Bastable, and group sales director, Alistair Hiscock, became joint owners of the business in 2007, having previously held minority shareholdings, and worked within the company since 1995 and 1988 respectively.

Having retained an emphasis on quality and technical innovation, today Flowplant supplies pumps and equipment to a wide range of industries, and a variety of different applications, from surface preparation in the marine sector, to process activities in the automotive industry. In excess of 50 per cent of Flowplant’s sales are exported to destinations as diverse as the US, Norway, China and Nigeria, as well as every country within the EU.

“We estimate that approximately 80 per cent of our products are sold as a result of repeat business, which is why our quality and level of customer service is so important to us,” explains Mark. “Whilst the longevity of the products means that we may not see a customer for several years after they make a purchase, they do tend to look to Flowplant when they need further equipment. However we do not take this for granted – we are aware that in order to maintain our success we have to continuously work to improve and refine our offering.”

“We estimate that approximately 80 per cent of our products are sold as a result of repeat business, which is why our quality and level of customer service is so important to us,” explains Mark. “Whilst the longevity of the products means that we may not see a customer for several years after they make a purchase, they do tend to look to Flowplant when they need further equipment. However we do not take this for granted – we are aware that in order to maintain our success we have to continuously work to improve and refine our offering.”

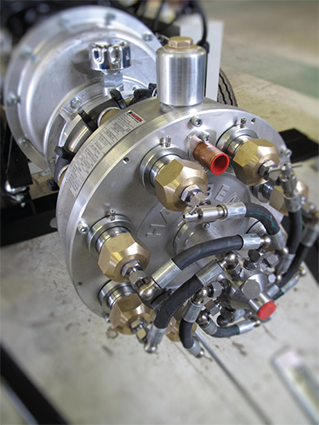

This client base includes a number of significant companies in the oil and gas sector, such as Haliburton, Alcatel, Nexen, BJ Pipelines, Oil Spill Response, Proserv, EnerMech, and Subsea 7 (formerly Acergy). Mark highlights some of the more common pump systems delivered to this market: “Radial piston diaphragm pumps are one of the primary products we sell to the oil and gas industry. This includes the ‘Century’ with maximum pressure up to 700 bar and flows up to 155 litres per minute (ltrs/min), and ‘P Pumps’, which have a maximum pressure of 420 bar, and flows of up to 70 ltrs/min. However, we are seeing more demand for the Aqua pump as part of hydrostatic test rigs, and for hot water jetting equipment in applications such as oil spill response. Given the operating environment of these companies, we also offer a range of ATEX approved pumps.”

Flowplant prides itself on the wealth of experience its workforce has in both its products and industries, with some individual members of the team boasting more than 30 years expertise. Supporting these skills is the business’ strong supply chain, made up of companies that share Flowplant’s commitment to delivering products of the highest quality. In particular the Harben pump range is built to aerospace tolerances, a level of precision that would not be possible without the expertise of these suppliers.

These capabilities also play an essential role in the development of new advanced technologies and bespoke products, as Mark notes: “Whilst many of our customers buy standard products or bare shaft pumps, there are a growing number that look to Flowplant for solutions to a particular problem, or application. We have a technical department that is well versed in supplying our clients with turnkey solutions based around our existing range of equipment, or something more unusual.” Flowplant is also currently working with the Manufacturing Advisory Service (MAS) on a number of developments aimed at improving pump characteristics and performance.

Whilst the performance of Flowplant’s products is well tested, the actual conditions present in its clients’ operational environment’s can pose unique challenges. One such example is Flowplant’s role in Haliburton’s specialist subsea pigging and hydro testing operations. During these processes, a high-tech skid is lowered to the ocean floor enclosed in a crash frame. This skid houses a Flowplant Harben four-cylinder Century pump, which is powered by a hydraulic motor and controlled via an ROV. The pump is connected to the undersea pipeline, which then forces seawater into the line until the test pressure is reached.

“Haliburton Service Supervisor, John Christie, has reported that so far the equipment has operated perfectly up to 1400 metres below the surface. At this depth the pressure of the surrounding seawater is 140 bar (over 2000 psi) and this is acting on every part of the pump. If any of the seals should fail the pump would seize up, shutting down the entire operations, and when you consider the high operational costs of such activities this is not an option. However, over a 12 month period the Harben pump spent 200 days on the ocean floor without fault, and only required servicing after four years of operation, which demonstrates the quality of our equipment,” enthuses Mark.

As a company that serves many different markets, both in terms of industry and geography, Flowplant has remained relatively secure in the face of the recent economic downturn. In terms of continuing to drive the business forwards, Mark concludes with how Flowplant’s plans for expansion will not negatively detract from its superior customer service: “We intend to remain focused upon our core business, while expanding organically and by acquisition where appropriate. This strategy has already paid dividends, as our new customers have been impressed by Flowplant’s responsiveness, flexibility and desire to work to achieve clients’ goals. We also believe that the growing desire of our client base to follow a similar ‘core business’ approach will result in an increase in our service work, as they look to subcontract ancillary services.”

Flowplant Group

Products: Pumps