Thrustmaster

A thrust for life

Based in Houston, Texas, and with offices in Rotterdam, Singapore, Dubai, Brazil and India, Thrustmaster’s factory manufactures heavy duty, commercial marine propulsion equipment.

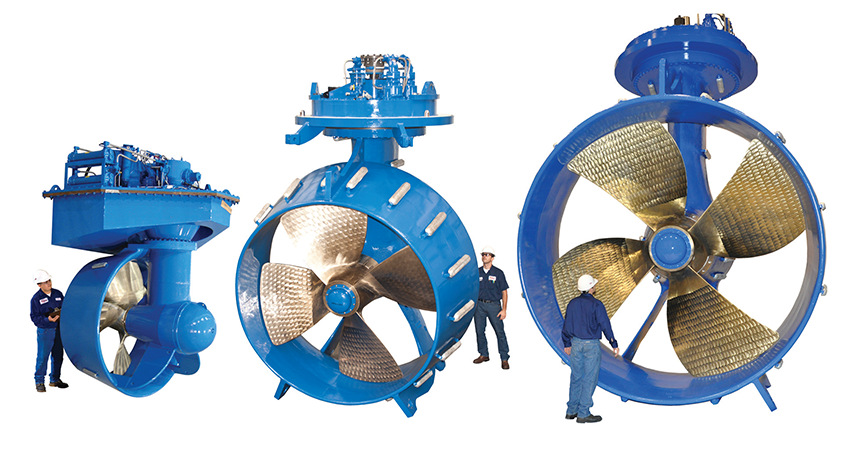

Coming in the form of deck-mounted propulsion units, thru-hull azimuthing thrusters, retractable and tunnel thrusters, Z and L drives and the company’s patented Portable Dynamic Positioning System, all its products are developed in-house by a complete engineering department of design engineers. Today this equipment can be found on offshore oil and gas exploration and production vessels, barges, PSVs, crew boats and numerous military applications.

A key contributor to the company’s success is its maintaining of a growing network of sales offices and well trained agents located all over the world: “Energy production occurs across the globe, and as such it has been a longstanding goal of Thrustmaster to build towards being able to meet the needs of the industry,” states Thrustmaster Europe general manager, Hans Hoek. “The way it does this is simply by listening to what its customers are saying.

“In Europe, the company has taken a lead on the rest of the market by responding early to the continent’s demand for renewable energy. In this field, Thrustmaster aims to develop or convert existing products, gearing them towards the needs of things like offshore wind energy projects. Nevertheless, while this move towards sustainable energy gains ground, it is important to remember that fossil fuels are still needed to make these transitions a reality. Therefore the company will continue to deliver outstanding products to the oil and gas market, while working with its partners to devise alternative solutions as the need arises.”

Thrustmaster’s first project was actually with what it describes as the largest customer one could hope for, that being the US Government. From that day on the direction the company has taken has been plotted by the needs of each customer it has come into contact with: “Thrustmaster’s strongest customer base to date remains offshore oil and gas suppliers, with the greatest level of demand coming from those that realise that the door to opportunity opens wider if allowed to do so,” Hans continues. “Recently the company made a multi-million dollar investment in a new factory, complete with new machines, in order to qualify for such large-scale contracts.

“When it comes to specific ships and barges, Thrustmaster’s work falls into the two categories of new builds and re-fits. For a new build project the company is typically contacted early on at the design stage, where it will then have the opportunity to bid based on drawings that have not yet been solidified. For re-fits the company is usually contracted to assist when said vessels’ mission is changed and its equipment has become outdated and would cost more to maintain than replace. The former category can often be more flexible since the products to be installed are not fully established, while re-fit projects can occasionally cause some angst, as there are often elements that cannot be changed Therefore, Thrustmaster must ensure it is able to make the necessary changes to its products while making sure its thrusters fit and work as they should.”

In recent months Thrustmaster has continued to aggressively fulfill dozens of contracts involving large thrusters in the 2500 KW to 4500 KW range for drill ships and semi-submersible rigs, which are being made ready for deep-water drilling. At the same time the factory is still fulfilling numerous orders for crew boats, OSVs, PSVs and towboats operating on inland rivers and harbours, and retractable thrusters for special lifting rigs.

Just one example of the type of project the company has recently been contracted to undertake involves the company McDermott and requires Thrustmaster to upgrade its heavy-life and pipe lay vessel: “Companies like McDermott have unquestionably earned their ranking in the marketplace, and in doing so they have taken on a lot of responsibility to fulfill their contracts,” Hans says. “That said, McDermott is well aware of the need to provide cost effective, efficient, stable, robust and responsive equipment, capable of performing all year round without fail. With this in mind it is fair to say that entering into a contract with such a company on such a large upgrade project is acknowledgment that Thrustmaster must be doing a lot of things right.”

Thrustmaster is a company that is fully aware that not only would someone be hard pressed to find two vessels that are exactly alike, but also that it can only truly prosper through the combination of excellent customer service and quality products that meet the demands of a complex industry: “With these facts in mind, Thrustmaster’s future will be defined by its ability to go on improving itself in the way it has, its ability to go on serving the diverse needs of the industry and its need to provide the kind of environment it is renowned for, one where engineering, production and quality control are expertly molded into one harmonious unit,” Hans concludes.

Thrustmaster

Services: Marine propulsion units