CS Combustion Solutions

Fired up

Made up of a team of senior specialists dedicated to innovation and dependability in the field of combustion technology, CS Combustion Solutions’ (CS) staff use their 25 years of expertise in engineering, supplying and commissioning of vertical and horizontal combustors for a wide range of applications to find the best results for each individual requirement.

“We are a company that specialises in combustion systems for the refinery and chemical industries, as well as the petro-chemical industry, developing tailor-made solutions for burning by-products. In the chemical industry this could be waste gas and waste air or solvents, which can be in any concentration and can be corrosive or not corrosive gases; the same is true for the burning or combustion of liquids. Meanwhile, for the refinery business, we have expertise for the thermal oxidation of liquids, gases and powdered solids that come from its byproducts,” explains Thomas Bartonek, managing director of CS.

Based in Vienna, the Austrian company’s team of 25 engineers offers tailor-made combustion services to its core customer markets throughout Europe, Russia, China and Brazil. As a member of the Unitherm-Cemcon Group, a successful producer of burners, kilns and furnaces since its inception in 1946, CS benefits from the resources and experience of its parent company, as Thomas elaborates: “We can exchange resources in terms of services and service staff and can work together in-house on burner management; even though we are in different markets we speak the same language and both specialise in burning systems.”

CS’ unique approach to the combustion process begins with the high-intensity mixing technology that forms the basis of all of its process burners. The mixing characteristics of its burners and chambers ensure incredible reliability and enable the client to achieve the lowest possible emissions. Furthermore, the company’s incineration processes have resulted in a large amount of unique innovations being introduced, which has led to ongoing developments in economical designs. Proud of its cutting-edge technology, CS offers advantages from both operational and cost perspectives, such as excellent flame stability, low maintenance, energy cost savings and high turndown ratios.

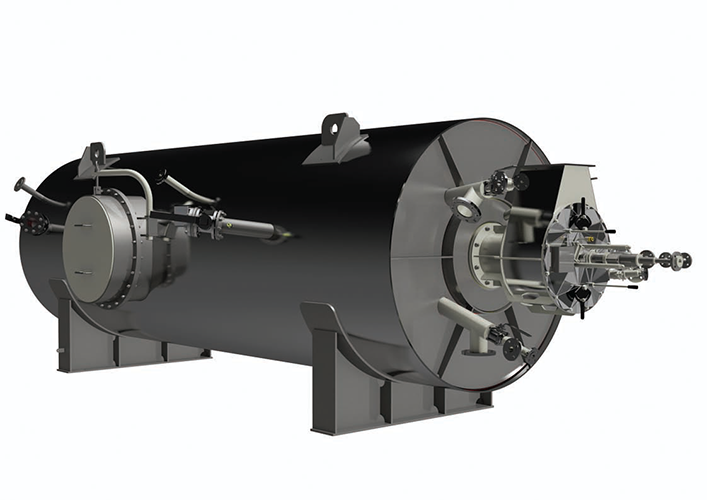

The products and services available can be divided into four categories: burners, combustors, injection systems and engineering & service. The vertical and horizontal burners and combustors are used for sulphur, spent acid and acid gas; waste gas and waste air, waste water, hazardous and special waste liquids and pasty waste fluids. “We are delivering complete burning and combustion systems, not only doing the engineering but the hardware as well. We do everything from the engineering, design, and manufacturing with our partners in Austria, Italy, Hungary and the Czech Republic, we then do the complete commissioning and start-up,” highlights Thomas.

Built according to EN, ASME & GOST standards, the burners are supplied for special applications with a performance range between one and 90 megawatts. Customised and designed to specific requirements, the SWB Burner operates on a range of standard and special fuels, such as NG, diesel fuel, HFO, H2S-gas, Tailgas and coke gas, which can be injected directly and simultaneously into the burner. Fields of application include industrial boilers, rotary kilns, combustors, static incinerators, O2 applications and furnaces.

Built according to EN, ASME & GOST standards, the burners are supplied for special applications with a performance range between one and 90 megawatts. Customised and designed to specific requirements, the SWB Burner operates on a range of standard and special fuels, such as NG, diesel fuel, HFO, H2S-gas, Tailgas and coke gas, which can be injected directly and simultaneously into the burner. Fields of application include industrial boilers, rotary kilns, combustors, static incinerators, O2 applications and furnaces.

Offering a one-stop-shop solution to its customers, CS delivers combustors for sulphuric acid production, SO2 production, spent acid regeneration, thermal disposal of waste gases, wastewater disposal and thermal disposal of hazardous waste liquids in the refinery, petrochemical, chemical and pharmaceutical industries. With more than 20 years experience in the design and supply of thermal oxidisers and firing systems, the company provides a full range of engineering and supply services including problem evaluation, detailed engineering, selection of the lining materials, transport, erection and commissioning. “We are particularly focused on the refinery sector and on applications for waste gases and waste liquids that contain some sulphur or sulphuric acid, which is due to refineries desulphuring all of the crudes that need to be removed, which is where our combustors come in,” says Thomas. “As sour gases increase it is causing an issue in the oil and gas industry; we are doing more gas incineration in relation to sulphuric acid compound and are continuing to develop and design high turbulence combustors or combustion systems.”

A bespoke solutions provider, CS is dedicated to enhancing its existing systems and finding new solutions for the markets it operates in. This expertise and commitment to innovation has led to the company becoming one of the preferred suppliers of burner and combustors for Haldor Topsoe, a Danish catalysis company that develops process technology for petroleum refining and other industries. “Haldor Topsoe works with wet gas sulphuric acid technology, known as WSA, which recovers sulphur from off-gases and produces commercial-grade concentrated sulphuric acid; this is a contract we are very proud of,” enthuses Thomas. Other projects include a huge contract with a well-known refinery in Russia, which includes a combustion unit with combustor and fuel feeding lines on top of a waste heat boiler and steam drum. Furthermore, the company has also won an order for a waste liquid treatment plant in the UK and is awaiting commission for more than 15 burner systems for a huge incinerator plant in Singapore.

With the company’s projects becoming increasingly more global, the future of CS looks positive as it focuses on Brazil, as Thomas concludes: “We began developments in Brazil this year and plan to continue strategically targeting this market. Further ahead, we are already the preferred supplier for Haldor Topsoe and our goal is to be the preferred supplier for other firms too.”

CS Combustion Solutions

Services: Combustion technology